The Application Gallery features COMSOL Multiphysics® tutorial and demo app files pertinent to the electrical, structural, acoustics, fluid, heat, and chemical disciplines. You can use these examples as a starting point for your own simulation work by downloading the tutorial model or demo app file and its accompanying instructions.

Search for tutorials and apps relevant to your area of expertise via the Quick Search feature. Note that many of the examples featured here can also be accessed via the Application Libraries that are built into the COMSOL Multiphysics® software and available from the File menu.

Chemical Reactions and Soot Build-Up in a Diesel Filter

In this tutorial, a filter system for a diesel engine is modeled, including a soot layer development and oxidization. The build-up of the layer is held in check by both catalytic and non-catalytic reactions, where carbon is oxidized to carbon monoxide and carbon dioxide, which in turn ... Read More

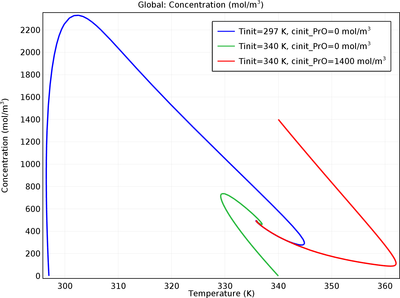

Startup of a Continuous Stirred Tank Reactor

The hydrolysis of propylene oxide into propylene glycol is an important chemical process with 400,000 metric tons produced worldwide each year. Propylene glycol finds wide application as a moisturizer in foods, pharmaceuticals, and cosmetics. In this example, the startup phase of a ... Read More

Pyrolysis of Wood

The pyrolysis of a centimeter-sized wood particle presents a fully coupled multiphysics problem with mass transfer, fluid flow, and heat transfer. This example model consists of two parts. The first part demonstrates how to set up a model describing the pyrolysis of a porous, ... Read More

The epitaxial growth of SiC by PVT method

Silicon Carbide (SiC) Epitaxial Furnace is a specialized equipment for the production and preparation of SiC Epitaxial Wafers. This model demonstrates the process of preparing SiC Epitaxial Wafer based on the Physical Vapor Transport (PVT) method in a furnace. This involves heating the ... Read More

Neutralization of Chlorine in a Scrubber

This example studies the kinetics of the neutralization of chlorine gas in water solution. The model assumes that the fluid volume is perfectly mixed and constant. This means that the chlorine has dissolved to an almost saturated state (1·10-2 mol/m3) and that the hydroxide has also ... Read More

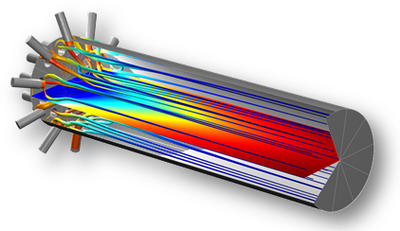

Polymerization in Multijet Tubular Reactor

In a polymerization reactor for polyester manufacturing, the mixing in the reactor is achieved by impinging turbulent jets of reactants onto each other. The turbulence affects the reaction kinetics and quality of the polymer linkage. Turbulent flows involving rapid reaction kinetics are ... Read More

A 3D Model of a Diesel Particulate Filter

Several factors influence a diesel particulate filter’s (DPF) efficiency and durability. Important issues include the removal of soot particles from the filter membranes and the influence of thermal stress on the ceramic structure, stress that arises during repeated operating cycles. ... Read More

Engine Coolant Properties

The engine block of a car includes a cooling jacket to remove excess heat from combustion. The cooling jacket consists of open spaces in the cylinder block and the cylinder head. When the engine is running, a coolant fluid is pumped through the jacket to keep the engine from overheating. ... Read More

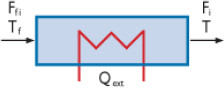

Nonisothermal Plug-Flow Reactor

This example considers the thermal cracking of acetone, which is a key step in the production of acetic anhydride. The gas phase reaction takes place under nonisothermal conditions in a plug-flow reactor. As the cracking chemistry is endothermic, control over the temperature in the ... Read More

Nonisothermal Reacting Flow in a Methane Steam Reformer

This model uses the Reacting Flow multiphysics interface to simulate a methane steam reformer. The model accounts for the interactions between the chemical reactions, the transport of species, the fluid flow, and the heat transfer in a porous medium. Read More