See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2023 Collection

Effect of KFm Airfoils Application on Aerodynamic Characteristics on the Example of NACA 0012

The paper presents of the application of Kline-Fogleman modified to determine aerodynamic characteristics and flow filed around the exemplary airfoil. This type of airfoil is currently used in models and small unmanned aircraft. Work on the use of this profile in larger aircraft is on ... Read More

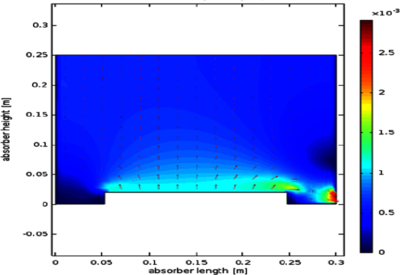

CFD Simulations to Improve Protein Separation Introducing a Permeable Surface with Periodic Grooves

In this study, we use COMSOL Multiphysics® to improve protein separations by the analytical technique asymmetrical flow field-flow fractionation (AF4). AF4 is a very mild separation technique where separation of macromolecules or nanoparticles takes place along a ribbon-like channel that ... Read More

Analysis of Asphalt Solar Collectors Using a Finite Element Approach

Current trends of research aims at the reduction of conventional fossil fuel consumption so as to mitigate anthropogenic global warming and thus to combat with the climate change. This can be done by shifting to more efficient, alternate, non-conventional and environmental friendly ... Read More

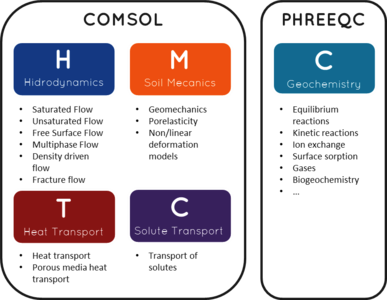

iCP Apps to Readily Solve Reactive Transport Simulations in COMSOL Multiphysics®

Reactive transport models (RTM) that couple physical and chemical processes are commonly used to solve a large variety of problems in the environmental industry. There are a series of codes designed to solve this kind of problems. However, their use requires typically much effort due to ... Read More

Interaction of Microparticles in a Miniaturized Vacuum-Cleaner

The ever-growing complexity of samples which need to be processed in e.g., environmental and biomedical/biochemical research, demand higher efficiencies of analytical techniques. Liquid chromatography (LC), mass spectrometry, among others, are analytical techniques that revolutionized ... Read More

CFD Investigation of Cross Bubbly Flow through a Bubble Column with Rectangular Geometry

Impact of human activities on the climate is evident, and the recent anthropogenic production and discharge of greenhouse gases into the atmosphere is highest in history. The current climate change have had worldwide influence on human and natural systems for example; global warming, ... Read More

CFD Investigation of a Photocatalytic Multi-Tube Reactor for Indoor Air Purification

In industrial countries, people spend most of their time indoors. Stringent heat-insulation measures in combination with deficient ventilation have a negative impact on indoor air quality [1]. Integration or retrofitting of a photocatalytic oxidation or PCO reactor into continuous flow ... Read More

Natural Convection Effects on the Solidification in Cylinders at Different Filling Percentages

The solidification of a fluid in a partially-filled circular cylinder is encountered in a number of industrial processes and in the oil and gas sector. The characteristics of the process depends on various fluid and geometrical parameters. In the current study, a fluid with temperature ... Read More

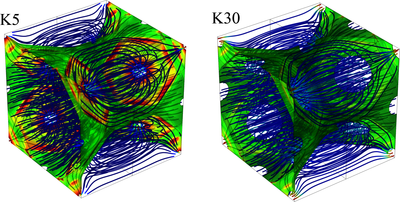

A Multi-Physics Study of the Wave Propagation Problem in Open Cell Polyurethane Foams

Flexible and semi-rigid polyurethane foams are widely used as noise and vibration damping materials. Their porous random microstructure is composed of a visco-elastic frame structure with an interstitial fluid, normally air, filling the voids. The viscoelasticity of the foams is due to ... Read More

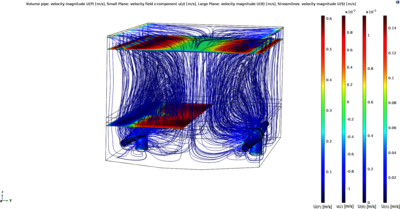

Fluid Dynamics Modeling of an Industrial Wet Chemical Process Bath for the Si-Solar Cell Production

Silicon solar cells are produced in a series of different process steps in which wet-chemical etching and rinsing steps have a considerable influence on the quality of the wafers. Etching baths are used for surface structuring or intended etch back. Examples therefore are texturing, ... Read More