A Multi-physical Approach of a Sterilization System for Aseptic Food Processing

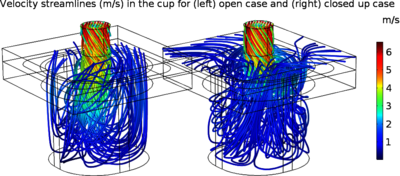

Sterilization is the process of deactivating microorganisms from a surface or a product. A high temperature gaseous mixture of hydrogen peroxide and steam became the accepted standard in most aseptic filling machines found in pharmaceutical, food and beverage industries [1, 2]. To achieve an adequate sterilization quality of surfaces in a machine operating at atmospheric pressures while maintaining safety guidelines for aseptic goods, a sterilization system is designed with three process steps. The first step is surface preheating by hot air, which is followed by surface treatment using the sterilizing gas mixture, and the final step is the surface post-treatment by hot air. The design of the sequential three-step treatment process is dependent on machine- and package-related factors. As a result, each of the three consecutive processes might require a single or a multiple delivery nozzle, with varying designs, flow velocity and temperature. For a cost-effective and efficient adaptation of sterilization systems to a certain package and filling machine type, numerical modelling using COMSOL Multiphysics® were exploited. In this work, each of the consecutive process steps of the sterilization system was separately investigated for an exemplary aseptic cup filling machine for dairy products. The general physics make-up of the 3D-treatment models includes a non-isothermal turbulent flow with heat transfer in solids and transport of diluted species. Due to the chaotic nature of the turbulent flow and to save computational resources, the convergence of the steady-state solution of the non-isothermal turbulent flow was assured by introducing a small isotropic diffusion coefficient to the Navier-Stokes equations. To identify key locations where the treatment gas did not come in contact with the package surface including the heat transfer to the container walls, a time-dependent solver for the heat and transport of diluted species was used. The latter physics serves as tracer in the preheating and post-treatment processes by increasing the discretization order of Fick’s diffusion law and introduce a small diffusion variable. On the other hand, to depict the non-isothermal mass transport of sterilization agent during the sterilization processes, a non-isothermal diffusion coefficient of individual gases constituting the sterilant mixture were utilized. Finally, to test different design parameters, such as the location of the nozzle and height above the cup container, a multi-parametric sweep in each process step was used and the most applicable solution or treatment strategy was carried forth to the next process step. Using COMSOL Multiphysics®, a qualitative representation of a sterilization system’s treatment process is possible. Therefore, adaptation of the sterilization system can be achieved in a time- and resource-effective way.

[1] Bockelmann, B. von and Bockelmann, I. von 1998. Long-life Products: Heat-treated, Aseptically Packed: A Guide To Quality. B. von Bockelmann Åkarp, Sweden. [2] Coles, R., McDowell, D. and Kirwan, M.J. 2003. Food Packaging Technology. Taylor & Francis.

Download

- jildeh_poster.pdf - 1.06MB

- jildeh_abstract.pdf - 0.08MB