Thermo-Mechanical Analysis and Fatigue Life Prediction for an Electronic Surface-Mount Device (SMD)

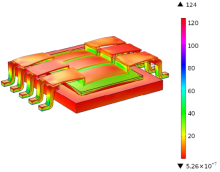

Electronic devices produce a very high rate of specific heat with respect to their dimensions. Exceeding in maximum safe operating temperature means strong reduction of efficiency, reliability and lifetime. In addition, electronic devices are subjected to periodical thermal loading. Combined with the thermal expansion mismatch between the different materials of the assembly, cyclic thermal loading results in stress reversals and potential accumulation of inelastic strain in the solder joint (fatigue mechanical stresses) ultimately causing solder joint cracking and interconnect failure. For those reasons, thermal design represents an unavoidable step in pre-production phase in order to ensure reliability and performance of the electronic devices. This paper deals with a steady thermo-mechanical analysis simulating the worst working condition for an electronic Surface-Mount Device (die switched on and maximum power supplied) in order to compute stress-strain distribution (Fig. 1) under assumption of elastic behavior for materials. A classical ultimate tensile stress (von Mises) analysis was firstly performed, then a thermo-mechanical analysis for «thermal cycles» simulation was performed in order to assess the fatigue life for solder joint under chosen conditions. To this goal, steady thermal states in two different ambient conditions (hot chamber and cold chamber) were computed and the consequent effective plastic strain distribution (Fig. 2) was estimated, giving as final result the number of cycle to failure under a Coffin-Manson approach.

Download

- petrone_poster.pdf - 1.08MB

- petrone_paper.pdf - 0.75MB

- petrone_abstract.pdf - 0.17MB