Characterization of The Physical Properties of Silicone

The following study was conducted to model the different behaviors of a material. The studied material is part of the elastomer’s family and is used in a wide temperature range from -55 ° C to + 135 ° C. This large temperature amplitude will generate behaviors strongly dependent on the temperature. Due to the great complexity of the internal structure of the elastomer, the resulting behavior is clearly non-linear.

A series of laboratory experiments were conducted on the material in order to obtain real data (Cycle tensile, Step wise and DMA). The experiments carried out highlighted a hyperelastic and viscoelasticity behavior. Additionally, the response depending of the temperature and the number of cycles (Mullins effect).

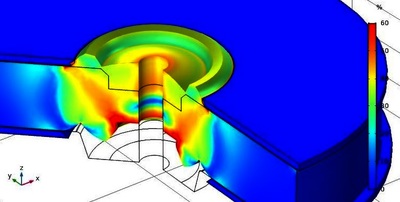

With the COMSOL Multiphysics® software the goal is to reproduce simulation experiments, allowing to reverse engineer and extract the right models to represent the material. Several material models have been implemented in the software thanks to the mechanical structural module. They were then compared to the experimental data using the COMSOL Multiphysics® Optimization module. Each behavior was initially identified separately.

Due to the allowed time and the used version of COMSOL Multiphysics ® (5.3)

Mullins effects parameters were put out of the scope parameters to identify.

Hyperelastic parameters were identified for the initial tensile step and the tenth tensile step. A model can be clearly identified as best representing the behavior of this material. Hyperelastics parameters were mapped in function of the test temperature and the nominal strain.

Viscoelastic models were identified. Parameters were identified for steps of the complete stepwise test. Nine parameters were optimized for this analysis. Complete stepwise test optimization wasn’t performed due to the allowed time and optimization set-up performances.

These studies validated that it is possible to modelized the non-linear material behavior of this elastomeric material.

In conclusion, the COMSOL Multiphysics®

software and its different modules made it possible to obtain theoretical / mathematical models allowing to represent certain isolated behavior of silicone. The ultimate objective, which is to simulate the combination of all the different behaviors simultaneously, has not been fully achieved.

The long-term objective of this study is to be able to simulate the behavior of silicone regardless of the shape of the component, stresses, strain applied, or the temperature used.

Download

- Poster_R_Paridant_124.pptx - 1.55MB