Modeling and Simulation of Multicomponent Adsorption of Organic Acids from Aqueous Solutions

Adsorption processes are widely used in the chemical industries for the bulk separation of gases and liquids, and in purification applications. These include the separation of oxygen and nitrogen from air, glucose/fructose separation, and in the purification of fluids. However, the separation of organic acids from fermentations and aqueous solutions is not well studied at present. The modeling and simulation of adsorptive separations involves the solution of a series of coupled partial differential equations (PDEs). These equations represent the transfer of solute from the fluid phase to a porous solid phase and diffusion into the solid particle. In the modeling of multicomponent adsorption in fixed-bed adsorbers, one set of PDEs representing flow of each component in the fixed bed, external mass transfer, and further diffusion of each component into the interior of the solid phase must be solved.

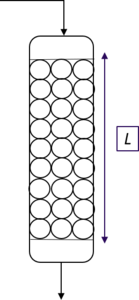

The mathematical solution to the general rate model was solved using the Reaction Engineering module in the COMSOL® software. For a single component, the mathematical model contains two PDEs, which were solved in a one-dimensional and a two-dimensional domain respectively. The domain is represented by a component, and hence a 1D and 2D component were chosen to solve the mathematical solution. The liquid phase mass balance equation was defined in a one-dimensional (1D) component with a geometry represented by an interval of dimensionless length of one unit. The pore phase mass balance equation was defined in a two-dimensional (2D) component with a geometry represented by a square with dimensionless sides of one unit each. In each component, the PDE was implemented using the coefficient form interface in the software. The extrusion coupling feature available in COMSOL® was used to define and share liquid phase and pore phase concentration variables between the components. Each equation was solved with its respective initial and boundary conditions for the liquid phase and solid phase components. However, in the case of layered beds wherein the adsorbent particles were stratified according to their particle sizes, the coefficients in the PDEs are different for each layer in the bed. In order to implement the mathematical solution for stratified beds, each domain was subdivided into a number of intervals based on the number of layers.

In the finite element method of solution, the mesh size determines the accuracy of the computed solution and its convergence to the true solution. Among the different methods for mesh refinement in COMSOL® , changing the element size is the easiest one. In this study, the mathematical model was solved using each of the eight available element sizes to confirm that the solution is grid independent. Increasing the element size to extra coarse reduces computational effort but leads to a less accurate solution, while decreasing the element size to extremely fine increases computational effort drastically. A fine to normal mesh element size was found to be optimal. This paper will present experimental results and simulation data for the adsorption of acetic and lactic acids from aqueous solutions at concentrations similar to that obtained from fermentations.

Download

- Alexander_Mathews.pdf - 2.49MB