Modeling of microstructure in a high temperature and pressure alkaline electrolysis cell

High temperature and pressure alkaline electrolysis is an innovative and promising technology for water electrolysis for hydrogen production. Introducing simulation at early stage development allows to study the effect of the microstructure parameters on performance and guide the development direction. In order to model the alkaline cells, several physics such as:

- Electronic transport

- charge transfer reaction (Butler-Volmer)

- ionic transport (migration and diffusion)

- diffusion of the dissolved gas

- bubble nucleation and growth

- bubble release and transport to macropores

- gas diffusion in macropores network

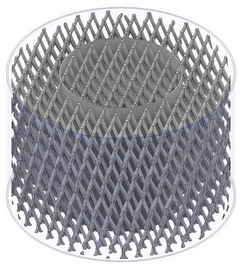

need to be taken into account. For this reason, COMSOL Multiphysics® has been chosen as software to develop the model. A sensitivity analysis on the effect of microstructure parameters such as electrode thickness, agglomerate diameter, mesopores size on the performance (overpotential) has been analyzed at different operating conditions. The range for the sensitivity analysis were the following: Agglomerate diameter: 1 – 2 – 5 μm Electrode thickness: 10 – 20 – 50 – 100 μm Mesopore size: 10 – 50 – 250 nm Operating conditions: o Set1: T=150 °C, P= 30 bar, 1 A/cm2, pH2O = 1.7 bar o Set2: T=200 °C, P= 30 bar, 2 A/cm2, pH2O = 6 bar o Set3: T=200 °C, P= 30 bar, 0.5 A/cm2, pH2O = 6 bar Random geometries in 2D at first and subsequently in 3D, based on these microstructure parameters have been created and meshed. The results showed that an electrode thickness larger than 50 μm would be beneficial, see Fig. 1, and bubble formation is not a risk for agglomerate diameters of interests, see Fig. 2.

Recorded Presentation

Download

- Matteo_Lualdi_comsol_conference.pptx - 14.73MB