Multiphysics Modeling of a Fluorine Production Cell

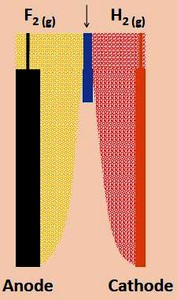

Gaseous fluorine plays a major role in the nuclear industry since it is used to produce uranium hexafluoride, whose physical properties are the key to classical uranium enrichment processes. The fluorine production process is based on the electrolysis of an anhydrous HF-composed molten salt which results in the production of fluorine at the anode and hydrogen at the cathode. Given the reactivity of the chemical species involved, simulation is a tool of choice to understand this process, to develop new technologies and to get access to local data. A 3D model of a R&D fluorine production cell has been developed using COMSOL Multiphysics®. Electrokinetics, two-phase flow and heat transfer are all taken into account to simulate the system. This model involves strong couplings and is a major step forward in scaling-up the simulations toward industrial production cells. The solidification of the electrolyte around the cooling system has been modeled for the first time at this scale. This feature is useful, in particular, to predict accurately the temperature field in the cell and close to the electrodes’ surface, which is the primary area of interest in this system. In the present work, simulated results are compared with experimental data acquired for this purpose. Experiments were realized for different HF mass fractions and intensities and key output parameters, such as the cell voltage, were measured. The three physics involved have been validated on the basis of this experimental work.

Download

- vukasin_poster.pdf - 0.9MB

- vukasin_abstract.pdf - 0.02MB