Shadowing Effects of Monofunctional Catalysts in TAP Reactors

Industrial catalytic processes require tailored catalysts with an optimized performance to reduce energy consumption and waste products. Besides an optimum temperature, pressure, and composition, the distribution of active material can be seen as a valuable additional design variable. The temporal analysis of products micro-reactor system [1] contributes to this challenge by reducing the complexity of the operating environment in which the catalyst resides. Therefore, reactants are pulsed at ultralow intensity into the reactor under vacuum conditions and thus the transport is well-defined Knudsen diffusion. Furthermore, in novel TAP experiments the reaction zone was reduced to a single micron-sized catalyst particle embedded in inert quartz particles, also referred to as “needle in a haystack catalysis”. Interpreting the reaction zone in the TAP reactor as a point source eliminates non-uniformities in catalyst composition, reactant concentrations and temperature profiles within the reactor. The aim of this study is to elucidate a shadowing effect, defined as the loss of activity of particles on approaching each other, on monofunctional catalysts in a TAP reactor.

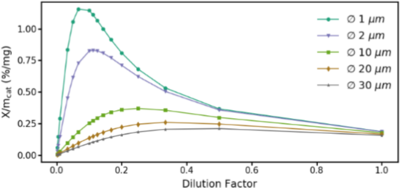

In order to vary the size of the active particles from microscale to nanoscale three different models were set up with Chemical Reaction Engineering module. In general, the diffusion-reaction behavior through the reactor is implemented by the Transport of Diluted Species and Chemistry interfaces. As a first model, highly active particles ranging from 50-250 micron in diameter are placed within the reactor system either in 3D or 2D when placed on the axis of the reactor. As a second approach, an active zone comprised of smaller particles (ø 0.1-30 µm) can be represented by the Reactive Pellet Bed feature in a 1D model. In a third and final model, particles are redefined in more detail, i.e. an inert support with metal deposited as nanoclusters on its surface. The support surrounding the clusters can serve as a precursor state, in which particles can be trapped in a physisorbed state and diffuse. In the latter model, a first component computes the area of a capture zone, in which diffusion towards a cluster is guaranteed, while a second component uses this area for homogenization of the particle’s surface. The three models were inspired on “Transport and Adsorption” and “Packed Bed Reactor 3D” models from the Application Libraries.

For a two-particle system in the first model shadowing is most prominent in the axial direction with a shift towards the inlet of the reactor when decreasing their size. In the second model an optimal dilution of the active zone can be found, at which the catalysts’ performance outweighs shadowing. The third model explains how capture zones extend the distance at which shadowing sets in. Moreover, overlap of the capture zones stabilizes the conversion of the system and therefore leading to high amounts of shadowing.

[1] Morgan, K., Maguire, N., Fushimi, R., Gleaves, J.T., Goguet, A., Harold, M.P., Kondratenko, E.V., Menon, U., Schuurman, Y., and Yablonsky, G.S. Catal. Sci. Technol., 7, 2416-2439 (2017)