See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2023 Collection

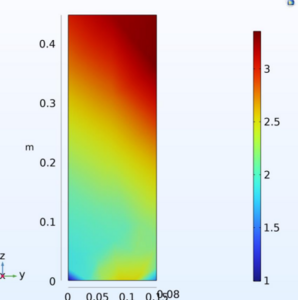

Electrical field effect on CO2 absorption and chemisorption in a rectangular bubble column by COMSOL

The chemisorption and absorption of CO2 bubbles have been extensively studied and modeled in literature. CO2 gas is converted into aqueous CO2, which produces OH-, HCO3- and CO32- - ions in the solution. In this study, a 3D CO2 bubble column is simulated using COMSOL Multiphysics, ... Read More

FEM-based Electrical Analysis of 3D-MOSFET

The fundamental and essential component of the semiconductor electronics industry is the Metal Oxide Semiconductor Field Effect Transistor (MOSFET). The 2D model of MOSFET is widely reported and available in the application library of COMSOL Multiphysics®. However, the 3D model of MOSFET ... Read More

Geometry Optimization of Enzymatic Electrochemical Glucose Sensor

Diabetes is a metabolic disorder that is on a rising tide. Diabetic patients must regularly monitor their blood glucose levels. One method for designing such a device is using electrochemical principles, specifically amperometry to determine glucose concentration. It is essential to ... Read More

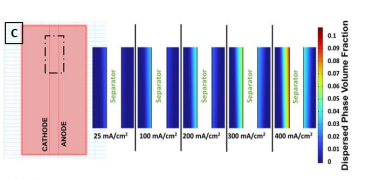

High Fidelity Multiphase Modelling of Hydrogenics in Zero Gap Alkaline Water Electrolyzer

Electrolytic hydrogen production stands as a beacon of promise within the realm of sustainable energy technologies, owing to its remarkable potential for yielding hydrogen with high energy efficiency and enabling long-term energy storage. Among the gamut of hydrogen production ... Read More

Beyond the limits of mass transfer: How pillar electrodes influence electrochemical reactors

Electrochemistry is inherent a surface process, requiring the transport of reagents towards the electrode surface. In electrochemical reactors this typically results in mass transfer limitation problems, limiting the yield and efficiency of the reactor. While the academic community is ... Read More

From the laboratory to the living room: COMSOL as a remote teaching and research tool

At University College London, Applied Analytical Chemistry MSc course, we have used COMSOL Multiphysics as an alternative to laboratory-based student research projects. Use of computational modelling enabled students to complete their research work remotely while gaining experience in ... Read More

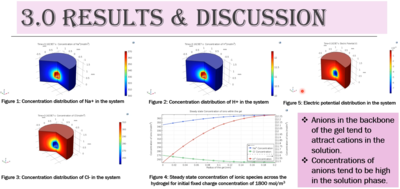

Multiphysics Simulation of the Swelling Kinetics of pH-Responsive Anionic Hydrogels

pH-responsive hydrogels have over the years drawn research interest in applications such as microfluidic control and separation, chemo-mechanical sensing systems and controlled drug delivery, owing to their ability to undergo significant volume changes in response to changes in pH of the ... Read More

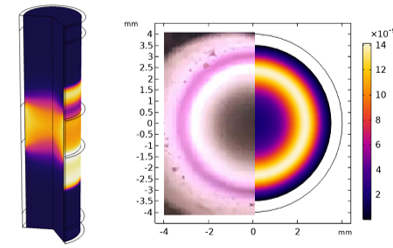

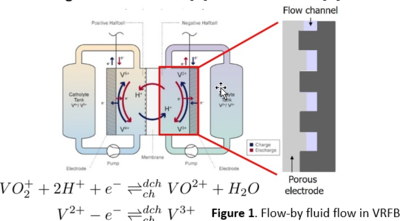

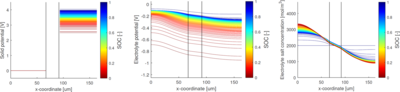

Fluid flow patterns and limiting current densities in vanadium redox flow batteries

The all vanadium redox flow battery (VRFB) is a promising electrochemical energy storage technology with the potential to play an important role in future power grids [1]. While the common VRFB cell design is planar, a tubular cell design might display advantages as reduced sealing ... Read More

Enhanced Physics-Based Models for State Estimation of Li-Ion Batteries

COMSOL Multiphysics® and the Batteries & Fuel Cells Module are used to create a pseudo 2D model of a Li-ion battery. A sensitivity analysis determines the most sensitive model parameters which are identified by microstructure analysis or optimized by nonlinear least-square regression ... Read More

Porous electrode optimization for an integrated photovoltaic-electrolyser

Photovoltaic-powered electrolysis (PV-EC) though the most mature technology for zero-carbon integrated solar to hydrogen conversion, is still only approaching industrial and commercial relevance, and devices with light absorber area larger than 100 cm2 are quite rare [1,2]. Here, we ... Read More