See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2023 Collection

Numerical Solution of Nonlinear PDEs Exhibiting Soft Bifurcations

This talk communicates a pseudo-dynamic approach to solve nonlinear stationary equations exhibiting soft bifurcations. The procedure consists in passing from the stationary partial differential equation - to an artificially-built pseudo-time dependent one. We construct the latter in ... Read More

Modeling Approach to Facilitate Thermal Energy Management with Phase Change Materials (PCM)

Thermal energy storage systems receive notable attention within the framework of energy management due to their ability of bridging thermal energy demand and supply, thus leading to an overall efficiency increase. The key component in such systems are materials which convert ... Read More

Laser-Material Interaction Modeling using the COMSOL Multiphysics® software

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. The objective of the work presented in ... Read More

Elucidating the Mechanisms of Charge and Temperature Modulated Ionic Transport in Nanochannels

The transport of fluid through nanochannels is of importance in a variety of technological applications, including biological sensing, energy storage and conversion, chemical separation and many others. Synthetic nanofluidic architectures that mimic the gating functions of biological ion ... Read More

Comprehensive Numerical Modeling of Filamentary RRAM Device

Resistive random-access memory (RRAM) is a non-volatile memory that operates via resistive switching between the insulating (OFF) and conducting (ON) states, representing the logical ‘0’ and ‘1’ binary states, in response to external bias. Attributes such as high memory density, fast ... Read More

A Heat Transfer Analysis of the Cochlea During Magnetically-guided Cochlear Implant Surgery

Approximately 450,000 people worldwide suffering from hearing problems use cochlear implants (http://www.cochlear.com/au/home/connect/cochlear-hearing-ambassador, June 12, 2018). Manual insertion of the cochlear implant during surgery can potentially damage the delicate tissues within ... Read More

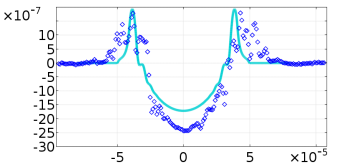

Time-dependent Thermoelectric Switching in Vanadium Oxide

We report the reversible thermoelectric switching [1, 2, 3] induced by a time dependent and frequency domain electric field (or AC voltage) in a microscopic single contact nano-device based on Gold and Vanadium Oxide, which promises potential applications for future information storage ... Read More

Thermoelectric Generators With Double Cooling And Novel Thermoelectric Materials

Recent developments (1) in thermal metamaterials that enhance the response of thermoelectric generators (TEG) have revived the interest in TEG research. The COMSOL Multiphysics® software offers the unique opportunity to model TEGs with various cooling systems (air, water, etc) and ... Read More

The Effect of Aluminum Content on Convective Flow of Molten Metal Generated by Arc Plasma

Arc plasma can heat and melt the metal material and flows of molten metal can be affected by several forces such as Lorentz force which is ruled by current, Marangoni force controlled by surface tension, buoyancy force, and arc drag force. Usually, surface tension variation is determined ... Read More

Steady-State and Transient Electrothermal Simulation of Microheater for Gas Sensing

Microheaters used for gas sensing applications have been studied analytically and experimentally. Previously reported microheaters at COMSOL® conferences have shed light on microheaters’ thermal properties, optimized geometries and power consumption—all based on steady-state analysis. In ... Read More