See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2023 Collection

Simulation of Through Air Drying in Tissue Paper in a Papermaking Process

Water removal during paper and board manufacturing is an intensive energy process. The dewatering process generally consists of four stages wherein the last stage is comprised by thermal drying in where remaining water in fibres are evaporated on steam-heated cylinders. The thermal ... Read More

Simulation-Based Sensitivity Analysis of the Direct Ammonia Fuel Cell Operating Conditions

Ammonia is studied both as a hydrogen carrier and as a fuel for renewable energy infrastructure. An important advantage of ammonia compared to carbon-based fuels is that it can be oxidized without greenhouse gas emissions, producing only N2 and water. Direct ammonia fuel cells (DAFCs) ... Read More

Thermal Conduction in Anisotropic Granular Mixtures

With the ongoing electrification of vehicles as well as rapid digitalization, thermal management is on everyone´s lips. This includes the use of ever-better materials, specifically tailored regarding their thermal properties. To fine-tune the thermal conductivity of a material, composite ... Read More

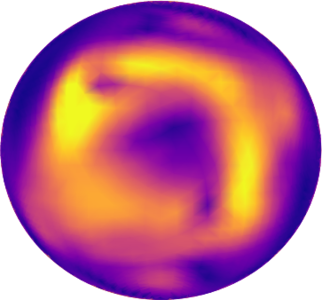

Towards Data Driven Design of Flow Blurring Atomizer

Liquid atomization relies on a variety of forces that disturb the surface of the liquid. In the case of flow-blurring (FB) atomization, turbulent structures are induced within the liquid channel to achieve this effect. It is known that the transition from the conventional flow-focusing ... Read More

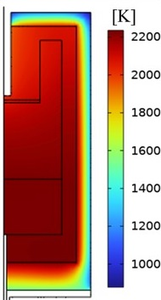

Uncertainty Quantification and Propagation in Multiphysics Modeling of the PVT Growth of SiC Crystal

The wide bandgap semiconductor silicon carbide (SiC) has drawn increasing attention in recent years as a promising material for high-power, high-frequency, and high-temperature operating devices. These outstanding properties of SiC make it a good candidate to replace silicon in many ... Read More

3D CFD Simulation of a PEM Fuel Cell Electrochemistry

Fuel cells are considered one of the most promising alternatives to conventional energy sources due to their high energy efficiency and only water from the exhaust. Accurate modeling of the fuel cell electrochemistry is crucial to optimize fuel cell performance. In this study, we ... Read More

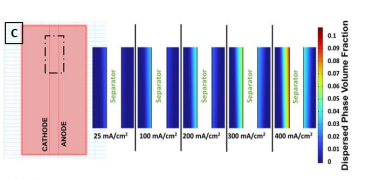

High Fidelity Multiphase Modelling of Hydrogenics in Zero Gap Alkaline Water Electrolyzer

Electrolytic hydrogen production stands as a beacon of promise within the realm of sustainable energy technologies, owing to its remarkable potential for yielding hydrogen with high energy efficiency and enabling long-term energy storage. Among the gamut of hydrogen production ... Read More

Improved CFD Simulation of Free Radical Polymerization in a Flow Microreactor with Additional Reaction Steps

The complete modelling of free radical polymerization (FRP) in a flow microreactor is dependent upon various transport processes - mass, momentum and heat transfer alongwith chemical reaction. And top of that, all processes are coupled to each other thus making modelling and simulation ... Read More

Non-uniform magnetic field-induced performance alteration of a topology-optimized PBMR

Packed bed microreactors (PBMR) and ferrofluids are independently enormously used in a broad range of applications in the healthcare sector. In a PBMR, one of the primary factors for controlling the reaction rate is the bed porosity which immediately affects the catalyst distribution and ... Read More

Beyond the limits of mass transfer: How pillar electrodes influence electrochemical reactors

Electrochemistry is inherent a surface process, requiring the transport of reagents towards the electrode surface. In electrochemical reactors this typically results in mass transfer limitation problems, limiting the yield and efficiency of the reactor. While the academic community is ... Read More