- COMSOL News 2025

- COMSOL News Special Edition: Food Industry

- COMSOL News 2023

- COMSOL News 2022

- COMSOL News 2021

Enhancing Transmission Line Performance: Using Simulation to Optimize Design

J. LemanPOWER Engineers, ID, USA

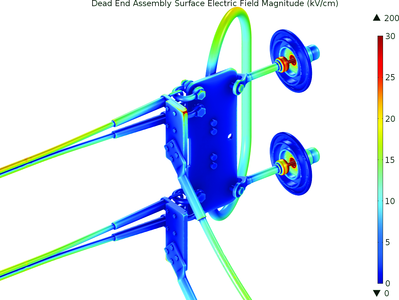

Designing power transmission lines requires accounting for many factors: mechanical stress due to environmental conditions and hardware loads, performance testing, and--of course--electrical analysis. Transmission line hardware contains both insulating and conducting assemblies. One common electrical phenomenon is called corona discharge, which occurs when electric fields near the surfaces of insulating assemblies and high-voltage conductors cause the surrounding air molecules to ionize. This can cause electromagnetic interference, visible light, energy losses, and audible noise. In a project to reduce corona discharge in transmission lines, Jon Leman, a senior project engineer at the consulting firm POWER Engineers, Inc. used COMSOL Multiphysics to model an insulator assembly. His team used their simulation to determine the electric field strength and electric potential around different surfaces of the transmission line hardware. They used their results to predict which areas were most susceptible to corona discharge, and gained valuable knowledge about how insulator assembly designs can be modified for better performance.

Simulation results showing the electric field strength on the surfaces of an insulator assembly. The regions with the highest electric fields are at the mounting pads and the pins connecting the insulator units to the rest of the hardware.

Simulation results showing the electric field strength on the surfaces of an insulator assembly. The regions with the highest electric fields are at the mounting pads and the pins connecting the insulator units to the rest of the hardware.

Download

- POWER_Engineers_MS2014.pdf - 1.85MB