The Application Gallery features COMSOL Multiphysics® tutorial and demo app files pertinent to the electrical, structural, acoustics, fluid, heat, and chemical disciplines. You can use these examples as a starting point for your own simulation work by downloading the tutorial model or demo app file and its accompanying instructions.

Search for tutorials and apps relevant to your area of expertise via the Quick Search feature. Note that many of the examples featured here can also be accessed via the Application Libraries that are built into the COMSOL Multiphysics® software and available from the File menu.

An acoustic point source emits a pressure wave in water that travels toward a piece of glass. Cracks are formed and propagate due to high tensile stresses developed in the glass. A fully coupled acoustic-structure interaction problem including phase field damage in solids is solved in ... Read More

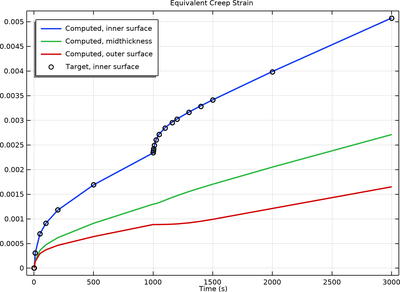

In this model example, you will study the creep behavior of material under non-constant loading. You will model the primary creep using a Norton–Bailey law and study the difference between the time hardening and the strain hardening methods available in COMSOL Multiphysics. The model is ... Read More

Powder compaction is a popular manufacturing process not only in powder metallurgy, but also in the pharmaceutical industry. The Capped Drucker–Prager model is commonly used for simulating the compaction processes of pharmaceutical powders, where the material properties depend on the ... Read More

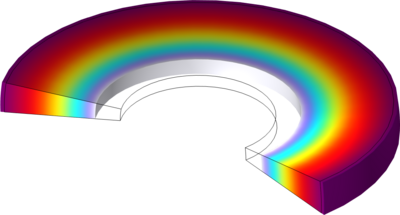

Diaphragm accumulators are essential components that store energy and regulate hydraulic systems. A flexible rubber diaphragm divides the hydraulic fluid from a compressible inert gas, typically nitrogen. These accumulators perform multiple tasks, such as temporarily storing hydraulic ... Read More

This model shows how you can implement a user defined hyperelastic material, using the strain density energy function. The model used is a general Mooney–Rivlin hyperelastic material model defined by a polynomial. In this example, you will see two material models based on the defined ... Read More

A thin-walled container made of rolled steel is subjected to an internal overpressure. As an effect of the manufacturing method, the out-of- plane direction has a higher yield stress than the other two directions. Hill’s orthotropic plasticity is used to model the difference in yield ... Read More

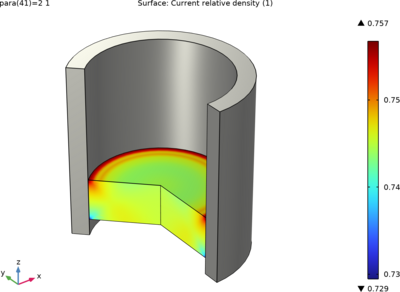

This model shows how to combine different types of material nonlinearity, such as creep and elastoplasticity. In this specific example you will perform a stress and nonlinear strain analysis on a thick cylinder under a nonproportional loading: an initial temperature increase followed by ... Read More

Creep is an inelastic time-dependent deformation which occurs when a material is subjected to stress at sufficiently high temperature, say 40% of the melting point or more. Experimental creep data (using constant stress and temperature) often display three different types of behavior ... Read More

A thin-walled container made of rolled steel is subjected to an internal overpressure. As an effect of the manufacturing method, one of the three material principal directions — the out-of- plane direction — has a higher yield stress than the other two. Hill’s orthotropic plasticity is ... Read More

This example illustrates how to combine different Creep material models. Here a Norton–Bailey model (primary creep) is combined with a Norton model (secondary creep). This example is a continuation of the model thermally induced creep. Read More