An Analysis of the Synchronous Transport Phenomena Involved in Pasta Drying Process

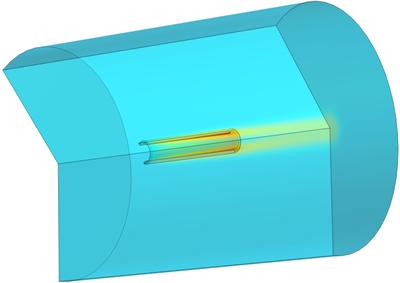

This work is focused on the development of a physical-mathematical model capable of predicting the temperature and water content fields within a pasta sample which is exposed to a stream of drying air flowing under turbulent conditions. Therefore, the equations concerning the transfer of energy (i.e. heat) and mass (i.e. water) were solved by discretizing the two domains (food and air) using the Finite Element Method and then numerically solved by the COMSOL Multiphysics® software. The aim of this work is to assess the best operating conditions to obtain a safe and high-quality product while trying to reduce the time and energy consuming process of trials needed to obtain the optimal process parameters. In particular, the implemented approach studied how the handling of the operating conditions during drying, such as air and food temperature and moisture content, influences the performance of the drying process. In order to compare results, numerical simulations were conducted on different geometries parameterizing initial conditions to typical values associated with industrial processes. One of them was assembled by following a condition of symmetry with respect to the r-axis (Figs 1, 2) and the drying air is supplied from top to bottom of the system. To achieve a flexible model, it was taken into account that the extruded pasta to be dried is a poorly porous medium and that the transport of water through the internal layers of the sample occurs exclusively in the liquid phase.The model completely disregards the use of the heat and mass transport coefficients at the sample-air interface, by solving the transport equations within the “food” and the “fluid” domains using a multiphysics coupling of the Turbulent Flow, Heat Transfer, and Transport of Diluted Species interfaces. It represents a powerful tool simulating the behavior of real dryers under a wide range of process and fluid-dynamic conditions. Hence, the two domains are appropriately coupled by means of a set of boundary conditions based on the explication of temperature continuity at the interface between the two phases and thus on the continuity of heat and matter fluxes. The model also implements the glass transition of the pasta sample, which induces important changes in its mechanical, rheological and transport properties [1]. Results were obtained through the evolution of multiple time-dependent simulations that take into account the physical characteristics of the samples as well as those of the drying air. In Figs 2 and 3 we can see the evolution of water content and internal temperature of the pasta sample, respectively, after the parametrization of the drying air temperature. Since the removal of water from a porous solid material is responsible for contracting stresses in the solid matrix [2] that can lead to “cracks” in the final product, as future perspectives of this work the modeling of the drying solid deformation will be developed.

Download

- Manoli_5331_presentation.pdf - 1.75MB

- Manoli_5331_poster.pdf - 10.88MB