See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2023 Collection

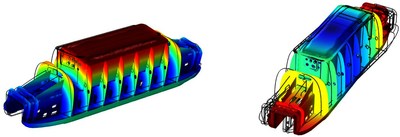

SpaceX Hyperloop Competition: Fluid Damper Optimization Through CFD & Multi-Body Simulations of The Prototype Dynamic Response to Stochastic Excitation

The EPFLoop team from Lausanne last year won the 3rd place in SpaceX’s Hyperloop Pod Competition in 2018. This year the team will participate at the 2019 Competition held at the SpaceX facilities California. Reliability of the different subsystems constituting the pod is a key point. ... Read More

Simulation of Silver Evaporation for A Knudsen Effusion Experiment Under Zero Gravity

Material constants are required to develop new materials for the aerospace, automotive and energy industries. With these highly accurate experimentally determined data, complex metallurgical melting processes can be simulated later, for example. The microstructure of the new alloy can be ... Read More

Modeling of the Viscous Flows in a Network of Thin Tubes

Flows in thin tubes arise in a wide variety of contexts like microfluidics and flows in blood vessels. Stationary laminar incompressible viscous flows in a thin tube were studied empirically and theoretically in the nineteenth century. They are described by the stationary Poiseuille ... Read More

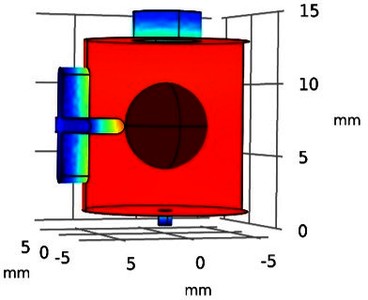

Experimental and Numerical Characterization of Supersonic and Subsonic Gas Flows for Nuclear Spectroscopy Studies

Noble gasses such as argon and helium are utilized within In Gas Laser Ionization and Spectroscopy (IGLIS) [1] and Ion Guide Isotope Separation On-Line (IGISOL) [2] techniques to thermalize and transport the nuclear reactions products, which often have short lifetimes and small ... Read More

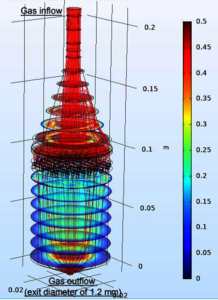

Modeling and Measurement of The Particle Size Dependent Residence Time Distribution in Spray Drying

Spray drying is one of the most commonly used methods to produce a powder out of a liquid and is widely used in the food industry. During spray drying, the liquid is atomised into hot air and dried in the drying chamber within seconds to minutes. The residence time, which is the contact ... Read More

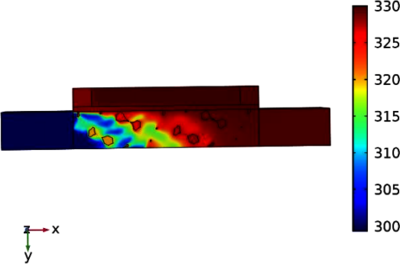

From the Laser Parameters to the Tribological Properties with COMSOL Multiphysics®

Whereas the physic models of fluid lubrication should be able to provide quantitative predictions to industrial problems, it is somehow demanding to provide the input data to feed these high-level equation systems. The operating conditions are generally available, and the material ... Read More

Dosing of Food Pastes – Modelling the Flow of Highly Concentrated Suspensions Through Straight- and Converging Pipes

Food pastes generally consist of a viscous liquid phase in which a high concentration of solid fillers is embedded and their production often includes a dosing step that involves high speed extrusion. Due to the high volume fraction of solid fillers, this extrusion is not only subject to ... Read More

Numerical Simulation of Air Permeability Coefficient of 3D Textile Layer

In recent decades, 3D fabrics are being increasingly used in aerospace, military, protection, sports and leisure and other industrial applications. 3D textile structures are formed from two fabric layers (top and bottom layer) combined by a spacer yarn or connecting layer. The ... Read More

Flow and Heat Transfer Through an Open Cell Metal Foam

Metal foams are interesting materials with many potential uses. They are characterized by a cellular structure represented by a metal (or a metal alloy) and gas voids inside. A common metallic cellular material is a solid sponge, also known as open cell metal foam. Due to their intrinsic ... Read More

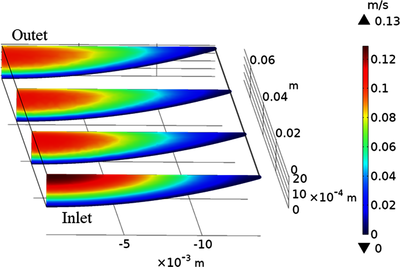

Modelling of a Thermal Time-of-Flight Sensor for Low Rate Open Channel Flow

Water transport in the public sewer system is often based on open channel flow, e.g. in a DN100 drainage pipe. Especially for low flow rates of less than 10 mL/s and with water levels of less than 4 mm, flow sensors are hardly available. In order to enable the measuring of very low ... Read More