See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

We present the design and performance simulations for a microwave cavity for use in novel compact cold atom atomic clocks. Design goals for such a microwave cavity are a resonance frequency at the Rubidium ground-state transition frequency of 6.835 GHz, combined with a moderate quality ... Read More

This study presents a numerical investigation of optical butt-coupling between Vertical-Cavity Surface-Emitting Lasers (VCSELs) operating at 850 nm and Standard Single-Mode Fiber (SSMF), a widely adopted configuration in cost-effective, high-speed optical interconnects, especially in ... Read More

A Laser-welded blank (LWB) consists of steels of different thicknesses and/or grades welded together to produce a single blank prior to the forming process. LWB are mostly used in the automotive field where the high productivity of the laser welding process is an advantage. Numerical ... Read More

The article deals with the magnetically-supported high-power full-penetration laser beam welding of aluminum. A stationary simulation was conducted accounting for the effects of natural convection, Marangoni convection and solid-liquid phase transition as well as an electromagnetic ... Read More

Quasi-static 2D-MEMS vector scanners are micro-opto-electro-mechanical systems (MOEMS) made of monocrystalline silicon. The primary application for these controllable micromirrors is the high dynamic and precise deflection of laser beams, for example in light detection and ranging ... Read More

The process-induced deformation in the DED fabricated part is a critical issue to the scaling of the technology. Currently, an inefficient and expensive experiment trial-and-error approach is utilized to tackle this issue, however it is not feasible for large parts. Researchers have ... Read More

A 2D axisymmetric model was considered in order to evaluate the propagation paths of the ultrasonic waves generated inside an aluminum plate sample due to a rapid thermal expansion produced by laser pulse. Laser Doppler Vibrometer is used to experimentally validate the numerical results ... Read More

Accurate, real-time measurement of arterial oxygen partial pressure (PaO₂) is essential for managing respiratory diseases and critical care conditions. Traditional arterial blood sampling for PaO₂ is invasive, painful, and provides intermittent snapshots rather than continuous ... Read More

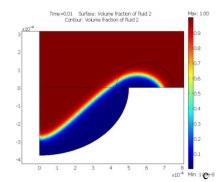

During the welding of tantalum with a ND: YAG pulsed laser, a deep and narrow cavity, called the keyhole, is formed. At the end of the process, surface tension forces provoke the collapse of the keyhole. For important interface deformations, gas bubbles can be trapped into the melting ... Read More

The Dynamic Transmission Electron Microscope (DTEM) at Lawrence Livermore National Laboratory is a unique instrument able to capture images of fast-evolving microstructure with exposure times of only 15 ns. This is more than six orders of magnitude faster than conventional in situ ... Read More