See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Magneto-Hydrodynamic (MHD) power generation systems were originally investigated starting from the fact that the interaction of a plasma with a magnetic field must take place at much higher temperatures than could be observed in a mechanical turbine. The main problems of traditional MHD ... Read More

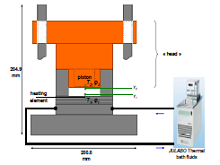

A new experimental device has been developed in order to characterize the phase change material (PCM) thermal properties (thermal conductivity k, sensible and latent heat thermal energy storage, cp and Lf) in the solid phase, during the solid-liquid transition and in the liquid phase. It ... Read More

A time-dependent COMSOL Multiphysics model of an additive manufacture process, which uses powder consolidation by laser heating was developed, providing a platform to better understanding the manufacture process & provide a tool to reduce resulting distortion & optimization of an ... Read More

The Dynamic Transmission Electron Microscope (DTEM) at Lawrence Livermore National Laboratory is a unique instrument able to capture images of fast-evolving microstructure with exposure times of only 15 ns. This is more than six orders of magnitude faster than conventional in situ ... Read More

An inactive Demonstration facility for the integrated pyroprocess, named High temperature Electrorefining (HTER) facility is in developing stage. This facility is equipped with several types of pyroprocess equipment such as electro-refiner, salt and cadmium distillation equipment, ... Read More

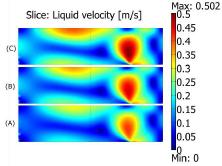

Flows of electrically conducting liquids in external magnetic fields are present in several applications. In this kind of flow, the inhomogeneous magnetic field creates a breaking force on the conducting fluid. As a result, a stagnant zone is formed in the zone affected by the localized ... Read More

In the steelmaking processes, the stirring of the metal bath by argon (or nitrogen) injection is a widely used method to achieve chemical or thermal homogeneity. Computational fluid dynamics can be used as a very powerful tool to gain an insight into the mass transfer and heat transfer ... Read More

Introduction: Glass relaxation occurs in a range of temperature during transition from equilibrium to super-cooled liquid. Viscoelastic material model can be applied to simulate glass behavior during the glass transition regime and to predict the glass deformation and stress evolution. ... Read More

In this paper, we simulated the heating of a work piece by coupling two heat sources. Concentrated solar energy was applied at the bottom of the work piece, which generated a heat flux from the parabolic solar dish concentrator. Subsequently, induction heating was applied, which ... Read More

In this work the innovative concept is the use of a Cu based metallic foam, characterized by open cell structure, as active element for heat exchangers. The metallic foam, produced by liquid infiltration method, was introduced inside a Cu tube, as base element for the exchanger. In the ... Read More