See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

For certain classes of scientific and technical computations the cloud may offer easily accessible, scalable, and affordable gigantic computing power. A power that for these classes may lead to a step change in model and analysis complexity compared to what is feasible with dedicated ... Read More

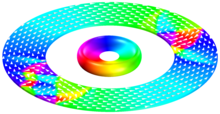

Ferrofluid sloshing vibration energy harvesters are the recent addition in the domain of vibration energy harvesting systems. These systems are unique in their use of a liquid state transduction mechanism to harvest ambient vibrations/oscillations to generate electric power. In this ... Read More

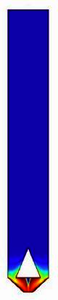

Hydrogen, the most abundant element in the universe, has great potential as an energy source, and can be generated from renewable energy sources. We used COMSOL for the solution of the energy, mass and momentum balance equations that describe the hydrogen absorption and desorption ... Read More

Hydrogen storage in a metal hydride bed, uses an intermetallic alloy that can absorb efficiently high amounts of hydrogen by chemical bonding resulting to metal hydrides. This alloy is capable of absorbing and desorbing hydrogen while maintaining its own structure. The heat, mass and ... Read More

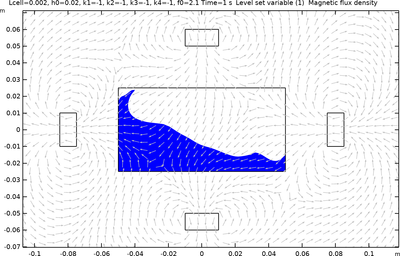

The modeling of ferromagnetic materials is a challenging task of high industrial and academic impact. Thin film and granular systems form the basis of novel spintronic devices such as modern hard drives with a high data area storage density. In order to push the current limits even ... Read More

Vanadium redox flow batteries (VRBs) are a promising new energy storage technology designed for use in long term applications such as uninterruptible power supply and coupling with renewable energy sources (i.e. wind and solar). Crossover is the undesired transport of vanadium ions ... Read More

The heat transfer rate and borehole design represent great challenges to thermal equipment designer of the ground-coupled heat pump. The present model represents a mathematical numerical technique implemented to tackle such problem. A thermal assessment was established to estimate the ... Read More

The unconventional shale gas reservoirs have a major contribution to hydrocarbon production in recent years. The hydraulic stimulation technique is being used to enhance the productivity of the target reservoirs. The drilled wellbore and existing natural fractures in the host rocks have ... Read More

Shielded transportation casks are commonly used for transportation and storage of radioactive waste materials. Design approval of such casks by regulatory authority is subject to its compliance with a thermal test (among other tests) Due to exposure of cask to fire , there is a ... Read More

The flow simulation of solid, particulate materials is still challenging, even though estimations show that three-quarters of products and raw materials are present as granules form in the industry. We can think of grain in the agriculture, raw materials of the glass industry, granulated ... Read More