See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

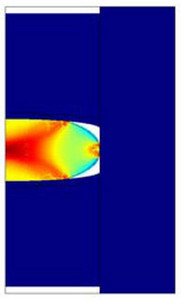

Jet Electrochemical Machining (Jet-ECM) is an unconventional procedure using localized anodic dissolution for micromachining. An increasing of the electrolyte temperature will lead to an increase of the electrical conductivity of the electrolyte by about 30% and to a reduction of the ... Read More

Capacitor Discharge Sintering (CDS) is an ultrafast Electric Current Assisted Sintering method (u-ECAS) suited for electrically conductive powders. It is characterized by relatively short processing times (milliseconds range) and much lower sintering temperatures than the melting point ... Read More

The excessive presence of residual SiC matrix inter-fiber pores is often the main cause for the very poor mechanical strength and toughness of SiC/SiC composites manufactured by CVI (Chemical Vapour Infiltration) process. This work presents a micro/macro Microwaveassisted Chemical Vapour ... Read More

Dynamic measurement of magnetic particles in continuous flow devices is made very difficult by the limitations imposed by the sensors themselves. Thus, certain sensor layouts are restricted to either number sensitive or spatial resolutive measurements of magnetic particles. We ... Read More

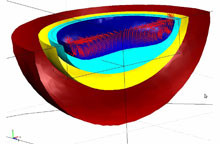

In this poster, a numerical model of spot pulsed current TIG welding for partially and fully penetrated weld pools is presented. Heat transfer and fluid flow in the weld pool driven by the combination of electromagnetic force, buoyancy force, surface tension gradient and latent heat are ... Read More

Fiber optic sensors can measure a large range of physical, chemical and environmental variables such as temperature, pressure, shape, position, chemical concentration, moisture, etc. Fiber optic sensors provide measurements in applications where the conventional electrical based sensors ... Read More

Corona discharge is used in several applications such as surface treatment of polymers, photocopying or dust removal in air conditioning. Streamer formation is undesirable for most of these applications. Therefore, several studies have been dedicated to investigate the formation and ... Read More

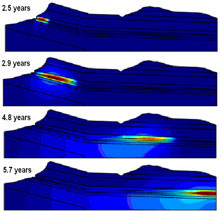

Radionuclide transport modeling is a part of the research concerning geological disposal of spent nuclear fuel. Typically, the transport models near a single deposition hole focus on the reactions of nuclides, while the model geometry and the flow of groundwater are often simplified. In ... Read More

Green house gases emission associated with natural hazard of underground coal seam fire has been recognized as a worldwide problem leading to global warming threat. Therefore, in this paper a model to study underground coal fire is presented and the results will be devoted to strategic ... Read More

The use of the finite element method for understanding and analyzing the freezing and drying processes of food products is in focus in this paper. The objective of this study is to develop a model that can predict temperature distribution and weight loss of food products during the ... Read More