See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Additive Layer Manufacturing (ALM) methods, like Electron Beam Sintering (EBS), constitute an interesting process concerning the production of small series and customized products. However, transient effects occur during processing due to the different physical principles of an electron ... Read More

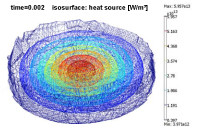

Additive manufacturing is attracting more and more interest. Laser Cladding is one of these additive manufacturing processes. For this a quasi-stationary physical based 3D process model is presented, which has been developed taking into account heat transfer, melt pool fluid flow ... Read More

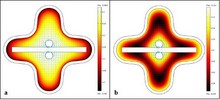

An interaction of aluminum aircraft skins with a laboratory-simulated, low-level, long-duration, continuing current representative of a natural lightning flash was modeled with COMSOL Multiphysics. For the analysis of the lightning direct effects on aircraft, the external environment is ... Read More

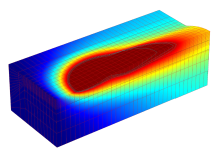

The Finite Element Method (FEM) has become an established numerical tool used for different academic and industrial purposes. It allows the prediction of weld pool geometry, thermal cycle, final distortion and residual stress field during and after fusion welding. The capability of the ... Read More

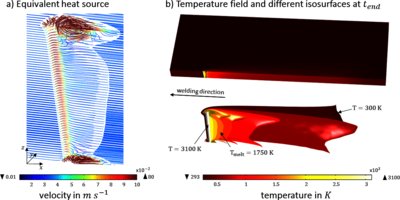

Arc current welding is a widespread process in heavy industry for the assembly of metallic components. In order to ensure the good quality of assemblies welds, it is appropriate to master the welding process but also to have a deep understanding of interactions with the weld pool and ... Read More

The interaction of high power laser beam with metallic materials produces a number of interconnected phenomena that represent a serious challenge for numerical modeling, especially for creation of auto-consistent models. Additional difficulty consists in lack of data on materials ... Read More

Improved performance of aeroengines requires the development of new manufacturing technologies for ceramic matrix composites (CMCs). This has been simulated using COMSOL Multiphysics. Specialized simulation technologies have been developed to describe the infiltration of molten material ... Read More

Thermal energy storage systems receive notable attention within the framework of energy management due to their ability of bridging thermal energy demand and supply, thus leading to an overall efficiency increase. The key component in such systems are materials which convert ... Read More

Sodium/metal chloride storage batteries, used in hybrid propulsion applications, provide high energy and power densities safely and reliably. To understand the dynamics of electrochemical cycling, a high-temperature sodium/ferrous chloride storage cell was modeled in two dimensions. The ... Read More

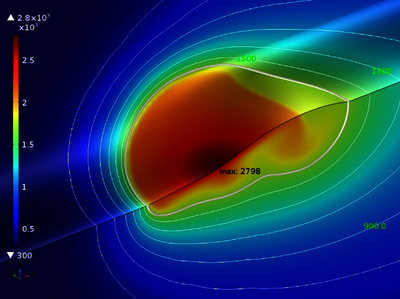

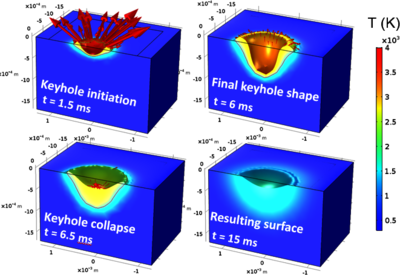

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... Read More