See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

Surface engineering is a key technology used in a wide range of sectors in industry. Among other techniques, it involves adding functionality to a surface. This can be performed by creating a specific topography to a surface using laser texturing. The objective of the work presented in ... Read More

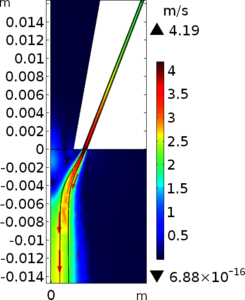

High power CO2 lasers have been the workhorses for sheet metal cutting, welding and many more applications in materials processing during the past decades. Even though a significant replacement by fiber coupled lasers takes place, there are still many applications that benefit from the ... Read More

Laser metal deposition is widely adopted for coating, reparation and 3D printing. Using COMSOL, we have developed a numerical model with full coupling of laminar fluid flow and heat transfer. The Marangoni effect is considered to capture the enhanced convective heat transfer as well as ... Read More

Graphene, as a two-dimensional material with exceptional physical and chemical properties, exhibits highly tunable optical absorption within the visible spectrum. Its absorption is sensitive to polarization, the number of layers, and incident angles, making it an ideal candidate for ... Read More

The Laser Metal Deposition process (LMD) is a rapid free form fabrication method which can be used to manufacture new near net shape metallic components, to repair used ones or to add functional parts on existing ones. This process is composed by multiple gas streams flowing inside a ... Read More

The IR CO2 laser powered chemical conversions in the gas phase are intriguing and the researchers’ attention was focused on this transformation a while ago. The method, known as Infrared Laser Powered Homogeneous Pyrolysis, or IR LPHP opened reaction pathways not reached by conventional ... Read More

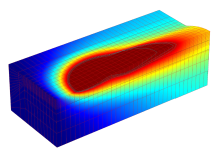

Additive manufacturing is attracting more and more interest. Laser Cladding is one of these additive manufacturing processes. For this a quasi-stationary physical based 3D process model is presented, which has been developed taking into account heat transfer, melt pool fluid flow ... Read More

Spot laser welding is largely used in industrial manufacturing, especially in the case of small penetration depth. Unfortunately, welded joins are often polluted by porosities. The formation of porosities depends on complex thermo-hydraulic phenomena. During the interaction, a deep and ... Read More

Laser-based powder bed fusion (LPBF) is a promising additive manufacturing technology, where metallic parts are produced in a layer-wise manner. At each step, a rapid-moving laser irradiates and subsequently melts predefined zones of a relatively thin layer of fine spherical metal ... Read More

Accurate tissue mechanical properties are essential for simulating medical devices that deform skin under suction, such as devices for the treatment of fat, skin wounds, and vascular skin conditions. While suction-based methods exist for estimating these properties, most rely on small ... Read More