See How Multiphysics Simulation Is Used in Research and Development

Engineers, researchers, and scientists across industries use multiphysics simulation to research and develop innovative product designs and processes. Find inspiration in technical papers and presentations they have presented at the COMSOL Conference. Browse the selection below or use the Quick Search tool to find a specific presentation or filter by application area.

View the COMSOL Conference 2023 Collection

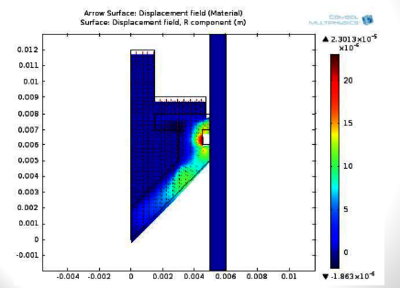

COMSOL® Modeling and Tensile Loading of Aluminum Material Test Samples

Material test samples are commonly subjected to tensile testing, with an extensometer used to measure changes in length of the material to determine strain. Lacking an extensometer, strain gages were used to measure longitudinal and transverse strain, with the location and magnitudes of ... Read More

COMSOL® Analysis-Led Design of Prototype Coil Program for Bi-2212 Coils

The National High Magnetic Field Laboratory (NHMFL) strives to push magnet technology to ever higher field strengths. Supported by a unified effort of material research as well as coil research, Bi2Sr2CaCu2O8+δ (Bi 2212) technology shows promise as a high temperature superconductor (HTS) ... Read More

COMSOL Multiphysics® as a Tool for Biomedical Engineering Students to Harness Physical Processes

The field of Biomedical Engineering is expanding at an exponential rate. As we began to unravel clues about our complex biological vessels, we uncovered more questions than answers. Our collective curiosity has led biomedical engineering into a broadening field by study of physiological ... Read More

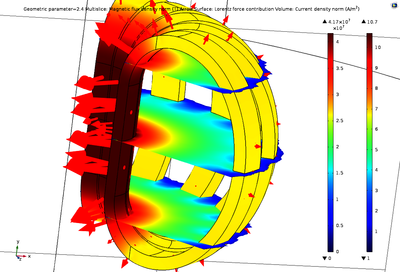

Analysis of D-Shaped Toroidal Superconductive Coils for Medium Size Fusion Experiment Facility

The research in magnetic confinement fusion is carried out through electromagnetic machines, with a toroidal geometry, where a hot plasma of heavy hydrogen isotopes (deuterium and tritium) is contained in a vacuum vessel. Due to the very high temperatures reached by the plasma, strong ... Read More

Tribological Behavior of Rubber on Glass in Prefilled Syringes

The primary enclosure of an injected formulation is almost exclusively comprised of a glass container (syringe) and an elastomer closure (i.e. plunger). A failed injection is anything that prevents the full dosage of the drug to be administered, whether that is a glass breakage or ... Read More

Thermal and Hydraulic Modeling of Road Tunnel Joints

This paper focuses on the use of the COMSOL Multiphysics® software to develop a 2D numerical model of expansion joints for road tunnels. The model was developed using the coefficient form PDEs interface. The model includes water and energy conservation equations. It takes into account ... Read More

The Roberval Balance

The Roberval Balance, invented in 1669 by French mathematician Gilles de Roberval, is a unique balance that has perplexed many upon first encountering the mechanism. This mechanism is a parallelogram that when its arms comprise a perfect parallelogram and the moveable weights or poises ... Read More

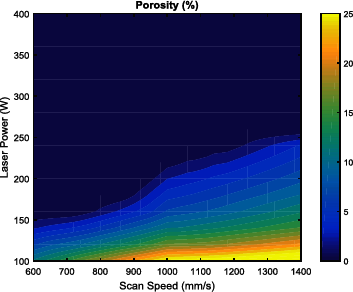

Simulation of Laser Powder-bed Fusion Additive Manufacturing Process Using the COMSOL Multiphysics® software

Additive manufacturing technology is becoming more popular for the fabrication of metal products as it offers rapid prototyping and large design freedom. However, part quality of components fabricated by current additive manufacturing technology is not comparable to that produced by ... Read More

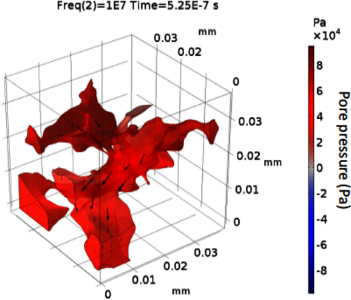

Numerical Simulation of Coupled Fluid-Solid Interaction in Digital Rock Samples

Digital rock physics (DRP) is an emerging field where a rock sample is imaged, relevant physical processes are simulated numerically on the digital rock sample, and the numerical solutions are used for understanding and interpreting the rock in different in-situ conditions. The use of ... Read More

Multiphysics Simulation of 2nd Generation 238Pu Production Designs Using the COMSOL Multiphysics® software

In order to qualify experiments for in-vessel irradiation at the High Flux Isotope Reactor (HFIR) at Oak Ridge National Laboratory, safety assessments need to be completed and documented to ensure adequate target cooling and structural integrity. Previously, finite element analysis ... Read More