Simulation of an Aerodynamic Furnace for High Temperature Thermodynamic Data Acquisition

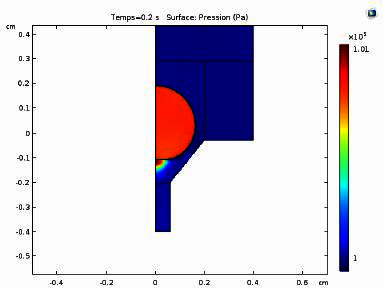

High temperature thermodynamic data are crucial for a wide variety of applications in nuclear and aeronautic domains as well as material production processes like glass formation or casting. Contactless acquisition methods are preferred to avoid chemical interactions with the container. A promising one is to use a spherical sample in aerodynamic levitation heated by a laser beam at temperature up to 3000 K [1]. Density can then be evaluated by an infra-red camera, surface tension and viscosity by analyzing the vibration frequencies and decay constants of the sample, as well as heat capacity by cutting off the laser beam and analyzing the temperature decay profile. Current evaluations of thermodynamic data are based on the hypothesis of elliptic deformation of the sample and predominance of radiative flux for the heat transfers between the sample and the environment [1]. Even if this seems in accordance with the image provided by the infra-red camera and the temporal profile of the temperature decay of the sample, some strange discrepancies appeared in experimental results for liquid alumina samples with the use of different gases and sample sizes, suggesting some unclarified interferences of the levitation gas [2]. We built a 2D-axisymmetrical finite-element model of the levitating device using COMSOL Multiphysics® Microfluidics and Heat Transfer Modules. We solved both heat transfer and compressible two phases flow equations using an adaptive moving mesh to insure the quality of the results. Comparison of the simulated results with different experimental data let us determine the influence of the levitation gas as well as the optimal size of sample for the levitation device.

References : [1] D. Langstaff, M. Gunn, G. N. Greaves, , A. Marsing and F. Kargl, Aerodynamic levitator furnace for measuring thermophysical properties of refractory Liquids, Review of Scientific Instruments 84, 124901 (2013) [2] Glorieux B., Mesure de la densité, de la tension superficielle et de la viscosité de l’alumine liquide en fonction de la température et de l’environnement, Phd Thesis, Université d’Orléans, 18/04/2000.

Download

- borgard_presentation.pdf - 0.63MB

- borgard_poster.pdf - 0.64MB

- borgard_abstract.pdf - 0.05MB