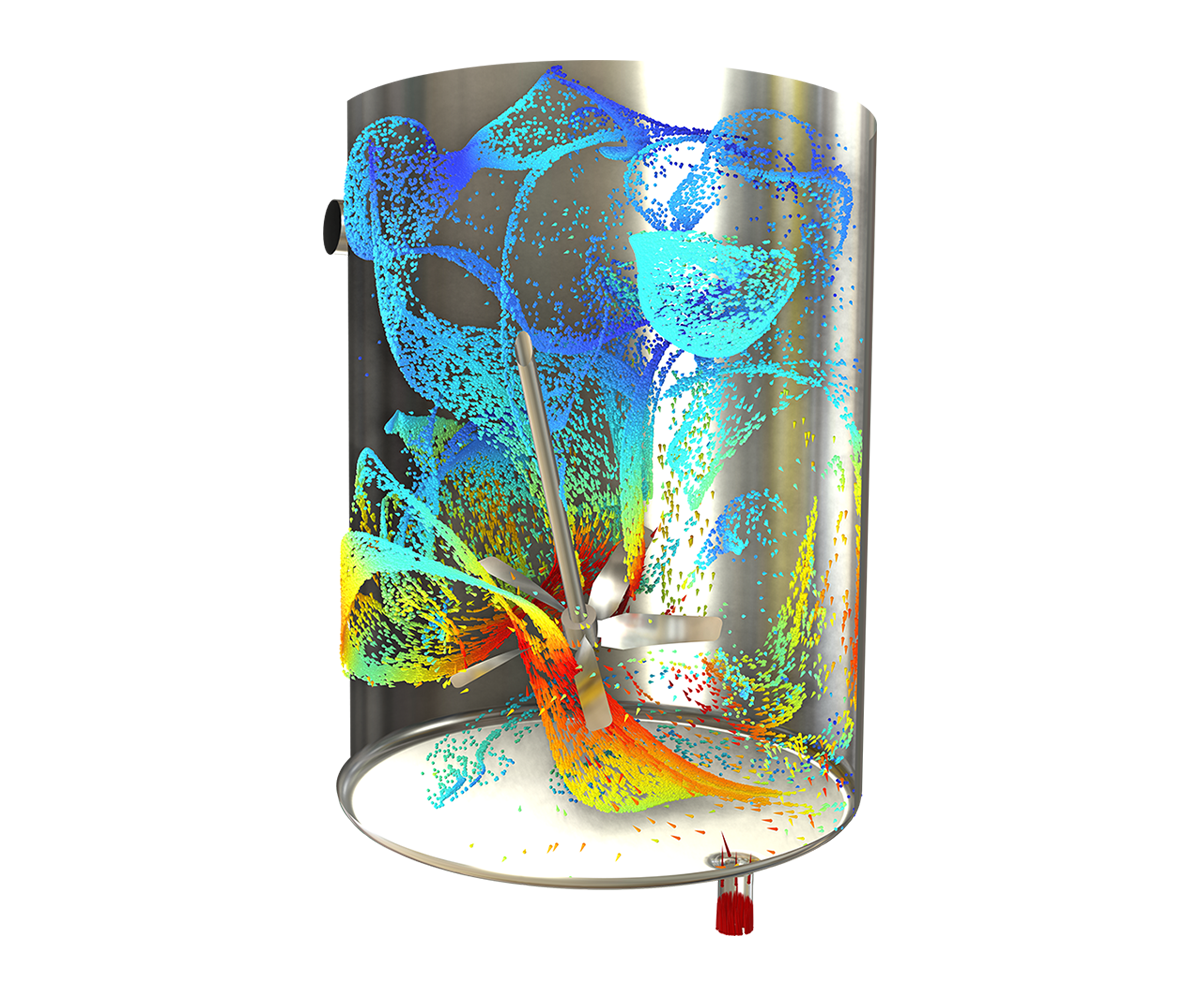

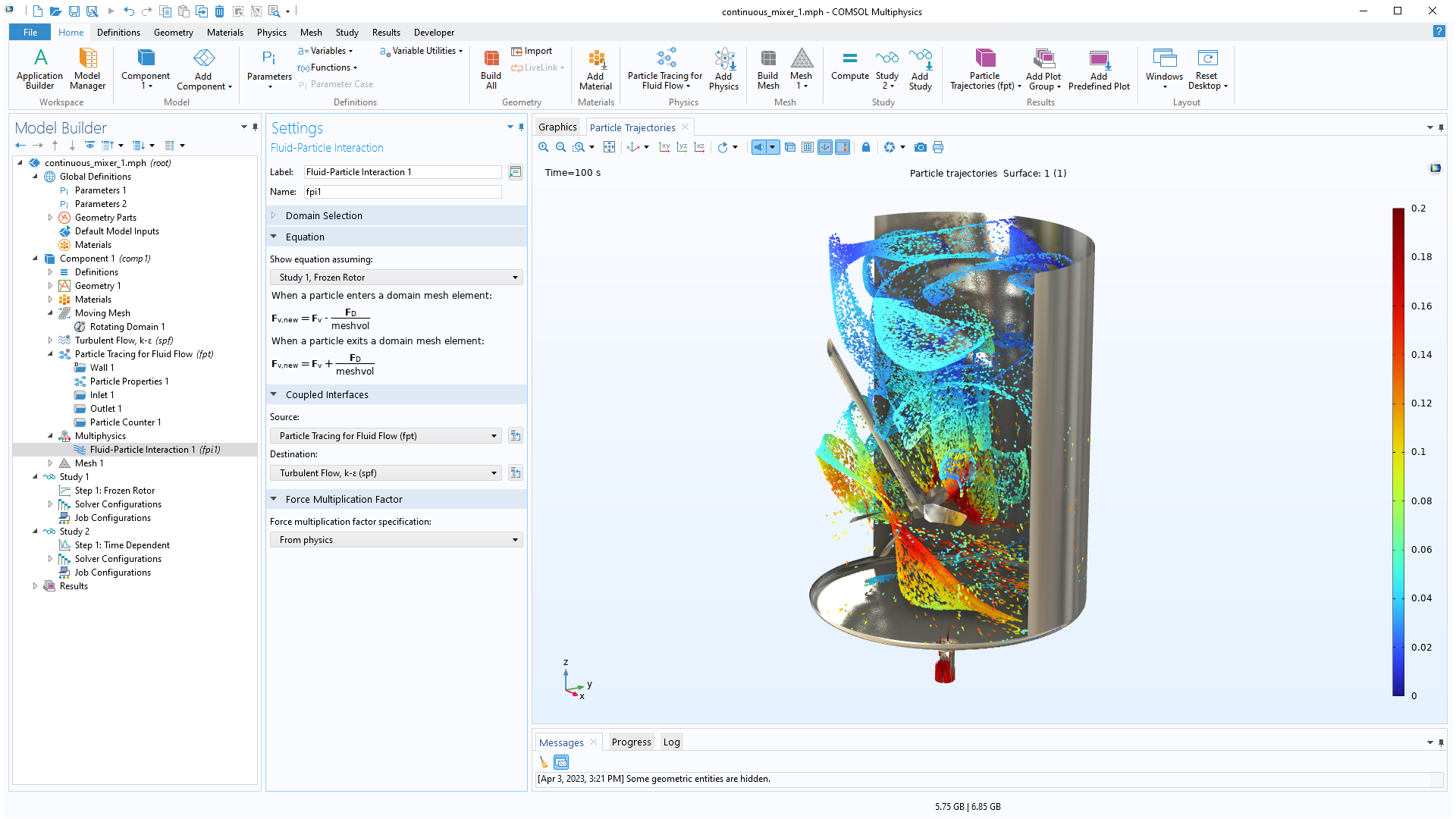

Fluid Mixing Simulations

In pharmaceutical, fine chemical, and food product processes, the quality, reproducibility, and uniformity of the products is of utmost importance. One way of making sure that these product requirements are met is to perform simulations in order to design and optimize the operation of the mixing process and the mixer or reactor itself. Models and simulations are particularly useful when they can first be validated by a pilot process and then be used for scale-up computations. Once validated, such models may be used to avoid the costs involved in building and running pilot-scale processes and instead go directly from lab-scale production to full-scale production.