The Application Gallery features COMSOL Multiphysics® tutorial and demo app files pertinent to the electrical, structural, acoustics, fluid, heat, and chemical disciplines. You can use these examples as a starting point for your own simulation work by downloading the tutorial model or demo app file and its accompanying instructions.

Search for tutorials and apps relevant to your area of expertise via the Quick Search feature. Note that many of the examples featured here can also be accessed via the Application Libraries that are built into the COMSOL Multiphysics® software and available from the File menu.

Drop tests are used to evaluate how consumer products respond to impacts and high accelerations. In this example, the Solid Mechanics, Explicit Dynamics interface is used to numerically simulate a drop test of a mobile phone, highlighting the permanent deformation of the aluminum case ... Read More

The fabrication of a cup through powder compaction is simulated in this tutorial model. The powder compaction process is becoming common in the manufacturing industry, due to its potential for producing components of complex shape and high strength. Combining the Fleck–Kuhn–McMeeking ... Read More

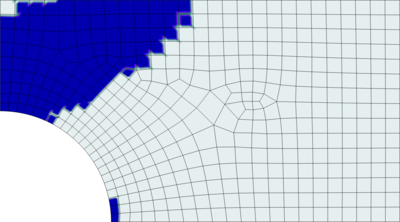

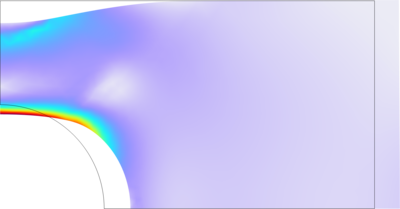

This example shows the analysis of a perforated plate loaded into the plastic regime. The purpose of the analysis is to demonstrate how plastic strains can be mapped between dissimilar meshes. Read More

This example shows the analysis of a perforated plate loaded into the plastic regime. Part of the example is a benchmark, which you can find in section 7.10 of The Finite Element Method by O.C. Zienkiewicz. The unloading of the plate and residual stresses are also studied. In a second ... Read More

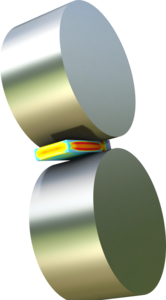

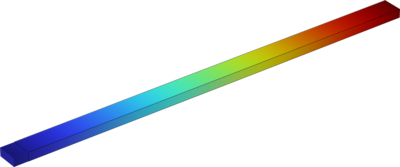

Roll forming processes are widely used in metal processing, battery electrode production and manufacturing processes. The model demonstrates the process of roll forming, where a workpiece is pressed after passing through a pair of rollers. The workpiece is carried between rollers by ... Read More

The elastoacoustic effect is a change in the speed of elastic waves that propagate in a structure undergoing static elastic deformations. The effect is used in many ultrasonic techniques for nondestructive testing of prestressed states within structures. This example studies the ... Read More

The model includes a compilation of benchmark examples included in the text book: Shape Memory Alloys: Modeling and Engineering Applications. D. Lagoudas Ed. Springer 2008. The model shows the thermomechanical properties of a NiTi alloy sample subjected to uniaxial tension-compression ... Read More

In this example, wrinkling is studied in a cylindrical membrane of nonuniform thickness under axial and pressure loading. The membrane is modeled as an incompressible Mooney–Rivlin material. During axial stretching, certain portions of the membrane undergo wrinkling; however, the ... Read More

Powder compaction is a key process in powder metallurgy, where it gives the flexibility to produce quality products of complex shapes for sintering. The density of the compact is a key factor to determine the overall quality of the sintered product, as regions with lower density could ... Read More

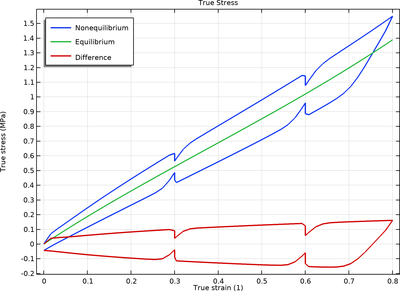

In this example, the Bergstrom–Boyce material model is used to capture the nonequilibrium behavior of carbon-black-filled chloroprene rubber under a strain history that alternates compression with relaxation. Results are verified against experimental and numerical results taken from ... Read More