3D Thermo-Acoustic Modeling of a Piezo Transducer for Directed Interstitial Ultrasound Ablation

Thermal ablation is a treatment option in oncology that can be used to target primary and metastatic cancers. In this approach, high temperature heating is administered at the target tumor site to induce coagulative necrosis of malignant cells. One minimally invasive method for administering thermal ablation is interstitial needle-based therapeutic ultrasound (NBTU). Here, the NBTU applicator is used to deliver a piezoelectric transducer to the target tumor location. When the transducer is electrically excited, high intensity acoustic waves are produced and absorbed by the cancerous cells, leading to localized heating and cell death. The use of a piezoelectric material by the NBTU approach offers good spatial control over the produced beam pattern as the geometry of the transducer can be manipulated to achieve a desired beam shape and directionality.

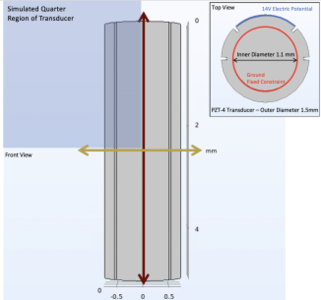

In this work, we present a three-dimensional (3D) model of an existing 90 degree directional piezoelectric transducer currently used by an NBTU applicator in pre-clinical studies. We extend our previously developed two-dimensional model and discuss the steps taken to move to a three dimensional model. An eigenmode analysis was conducted to evaluate the mode shape of the element. A frequency domain study was then conducted to compute the produced acoustic pressure field by the deforming transducer. This field was then used as an input to a bioheat transfer time domain study to determine the 3D heating pattern produced by this probe geometry. The results demonstrate the outcome for our NBTU applicator, but can be extended to other transducer geometries to inform studies focused on NBTU applicator design for cancer intervention. We also present an initial validation of our model by comparing the results with our physical NBTU applicator activated under MR-thermometry.

Download

- K_Gandomi-Comsol_Presentation_Final.pdf - 16MB

- K_Gandomi-COMSOL_2020_Poster.pdf - 1.26MB

- COMSOL_CONFERENCE_2020_Gandomi.pdf - 11.38MB