Analysis of Working Fluid Flow and Debris Behavior in Micro-EDM Gap Area

Published in 2013

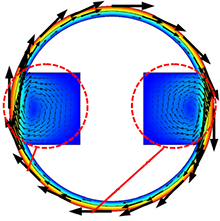

Debris, micro particles produced by discharges, stay in the gap area during deep hole machining by micro EDM, cause short-circuits and abnormal discharges, finally make machining impossible. Although a deep hole can be processed by using the tool with grooves on the surface, the effect of the tool shape on the flow of working fluid and the behavior of debris are not clear yet. In this research, the FEM model of working fluid in gap area was modeled in COMSOL Multiphysics and the flow of working fluid and the behavior of debris were analyzed.

Download

- MACHIDA_presentation.pdf - 2.17MB

- MACHIDA_paper.pdf - 0.48MB