Fresh Produce Safety During Hydrocooling: An Engineering Model

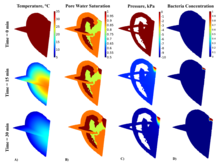

Hydrocooling is the process by which warm produce is chilled with water. The chilling of warm produce generates a negative pressure differential between the produce (warm) and (cold) water due to the condensation of water vapor inside the produce which forms a vacuum and can pull in contaminated water through an opening. A porous media based model of water infiltration was developed using a geometry acquired from MRI. Results were validated versus temperature, pressure, and moisture. The model results give a quantitative guide to improve food safety. Overall, the results show that temperature differential is not the only main cause of infiltration but process (heat transfer rate) and product parameters (porosity, initial moisture content, and permeability) also significantly affect infiltration.

Download

- warning_presentation.pdf - 1.32MB

- warning_poster.pdf - 2.79MB

- warning_abstract.pdf - 1.05MB