Heat and Mass Transfer Modelling in Lyophilization Using COMSOL Multiphysics®

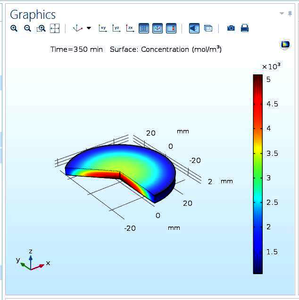

Lyophilization is a dehydration process used to preserve perishable material like food. It depends on many parameters like temperature, pressure, rate of drying, type of heating for sublimation, chamber size etc. Therefore, optimization of multiple parameters is required for design and development of a lyophilizer. In the present work, COMSOL Multiphysics® was used to model the governing equations for simulating the lyophilization of a fruit slice with the objective of designing a lyophilizer for preserving food for later use. The hardware used is HP-Z840 workstation. Numerical analysis has been performed by developing mathematical models of heat and mass transfer mechanisms for simulating the drying of an apple slice. The modeling of freeze drying process is a challenging task because of variable thermal properties of the material with respect to temperature and moisture content. COMSOL multiphysics software helps to couple the heat transfer and mass transfer models. In the present work, the developed simulation is confined to heat and mass transfer behaviour during drying of an apple slice, irrespective of the effect on biological aspects, to predict the temperature and moisture content of the apple slice during the drying process. The modules used for this purpose were – ‘Heat Transfer in Solids’ and ‘Transport of diluted species’ along with Freeze Drying model (Application ID 3924) from application libraries. This prediction was used to optimize the dominant process parameters such as target temperature and drying rate for the lyophilization process.

Download

- COMSOL_Bangalore_2019_VikasGarg.pdf - 0.24MB