Influence of Micro Gaps on the Magnetic Characteristics of FI Relay

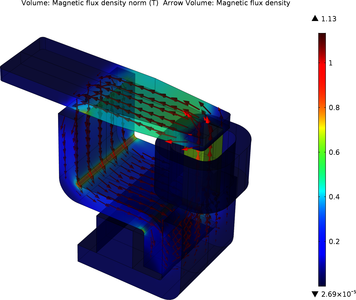

Various types of FI-Relays are built in electrical protective residual current devices (RCD). They are all electromechanical assemblies that trip at appearance of residual currents (i.e. fault or earth leakage current) and consequently break main contacts of RCD. FI relays are very sensitive components, because they must act reliably at very low tripping electrical power (μVA) that is generated by residual current. All of them are made of soft magnetic parts called anchor and yokes, permanent magnets, coils, springs and plastic parts. This research is about partial reconstruction of ETI's existing FI-relay. The goal was to achieve higher output mechanical forces (work) on FI-relay's striking pin, but its electrical tripping power and impedance must remain the same. Therefor we redesigned anchor positioning and replaced existing spring with torsion spring. To decrease mechanical deformation on anchor contact surface that limits required lifecycle test, we used additional thin non-ferromagnetic coating with high hardness properties on bottom anchor side. Coating presents new added micro air gaps between anchor and yokes and influence changes of relay's magnetic characteristics. We used AC/DC module to examine the effect of different coating thickness on electromagnetic properties of new relays. Results were later validated on physical prototypes.

Download

- strehar_poster.pdf - 1.05MB

- strehar_abstract.pdf - 0.13MB