Morphological Evolution of a Single Droplet Drying at High Temperatures

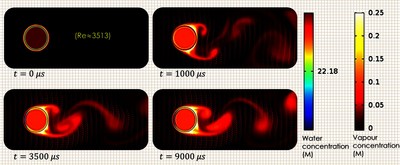

Single droplet drying (SDD) is an established experimental set up in which an isolated droplet is dried under a controlled environment. The drying behavior in the SDD experiments is often complicated and challenged to observe. Hence, a robust model of single droplet drying can provide an accurate prediction and potentially reduce experimental efforts. The project focuses on high temperatures drying due to the dramatic changes in particle morphologies above the boiling point. The COMSOL Multiphysics® 5.4 software was used to simulate the desired drying process of a single droplet. Theoretically, when drying above the boiling point, the droplet will have bubble nucleation and also form a hard-shell due to a high surface’s solute concentration. Hence, the main interest at this point is to understand how the bubble expansion interacts and deforms the solid shell through the liquid medium. Initially, an axisymmetric-1D drying system of a 1 mm sucrose-droplet was set up to validate against the available experimental results. The physics interfaces used consists of Transport of Diluted Species from the Chemical Species Transport branch and the Deformed Geometry interface from the Mathematics branch. The evaporation rate was set using the Flux boundary condition at the droplet surface. The receding interface due to evaporation was simulated manually using the Prescribed Mesh Velocity boundary condition. Subsequently, after validation, a bubble of 200 at the droplet center and a shell’s thickness of 300 was added. This problem set up was converted to the axisymmetric 2D system. Furthermore, the whole bubble-droplet system is placed within a rectangular domain with an air inlet and outlet at two horizontal ends in order to later validate with the single droplet drying experiment. The bubble contains air and assumed to be over-pressured initially. The liquid phase is incompressible and the skin layer is considered to be both porous and elastic. The physics interfaces used in this 2D component system includes the Laminar Two-Phase Flow, Moving Mesh interface, the Heat Transfer in Fluids interface and Solid Mechanics interface. The inward mass flux from the surrounding liquid was set at the bubble-droplet interface to accommodate for the bubble expansion. The 1D drying model showed a good agreement against the experimental data. The 2D system is expected to illustrate the ‘puffing’ behavior of the final particle since the droplet’s shell is elastic and the bubble expansion is symmetrical. The initial conditions such as the bubble and droplet initial sizes, the inlet air velocity, the shell elasticity or the initial bubble’s nucleation position can heavily influence the ‘puffing’ process. Due to the lack of understanding and established work in this field, the current model is expected to contribute to the construction of the morphologies map of a droplet drying at high temperatures. The implication of the project is to broaden the regime map of the dried-particle morphologies and hence advancing the ability to engineer the powder’s functionality to the required attributes in different industries.