Solving a Ceramic to Metal Seal Breakdown Problem Using Electric Field Modeling

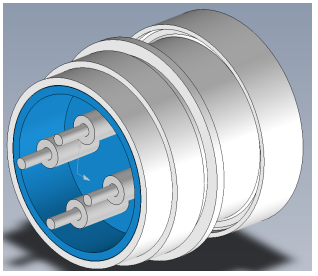

In the manufacture of radiation detectors, high voltage bias is often required. Since the detector is housed inside a sealed enclosure a ceramic to metal seal is used to feed this bias voltage to the detector as well as providing connections for the resulting pulse output from the detection of gamma or neutron radiation events. A problem with these seals was discovered which resulted in radiation events being detected when there were none present. This problem was exacerbated by elevated temperature which resulted in product failures since these detectors are required to operate up to 150º C. The AC/DC module and Electric Fields and Currents interface was utilized to characterize the fields within seal in hopes of highlighting any potential problem areas. The results showed very high electric field strengths due to small air gaps between the ceramic insulator and conducting pin which were in excess of the field strength required for air breakdown. In addition, the seal’s electrical characteristics such as capacitance and current paths through the insulators were also modeled. Incorporating these results into a simple electrical lumped element model allowed us to compare the model with actual failure modes and this analysis provided general agreement with the characteristics attributed to these invalid ”radiation” events. Finally, once the root cause had been identified it allowed us to develop a solution which so far has proven effective in solving the problem.