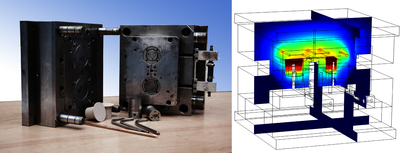

Thermal Simulation of a Heat Pipe Tempered Injection Mould Tool

An injection moulding tool developed by the FH Bielefeld is being displayed in a thermally precise way by means of COMSOL Multiphysics®. The tool is tempered through heat pipes. The performance of heat pipes is experimentally determined and depicted in a function. The function illustrates the relation between temperatures at the heat source and heat sink as well as the consequent heat flow in [W]. This function is assigned to the mathematical analogous model of the injection moulding tool at the mounting surface of the heat pipe. By way of real performance, depending on changeable temperatures of a heat pipe, COMSOL Multiphysics® is able to depict the thermal balance of the real injection moulding tool within the simulation model in every cycle. The Comsol model has been validated in practice. It could be ascertained that the extent of deviation between the real injection moulding tool and the simulation model is only little.

Download

- kartelmeyer_presentation.pdf - 0.63MB

- kartelmeyer_poster.pdf - 0.71MB

- kartelmeyer_paper.pdf - 0.52MB

- kartelmeyer_abstract.pdf - 0.32MB