Thermophysical model electron-beam treatment of titanium alloy VT-1

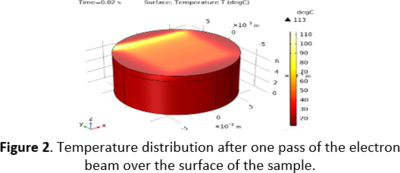

COMSOL Multiphysics® is a universal software complex based on the finite element method for computer modeling of physical problems. When modeling the electron beam processing process using the COMSOL Multiphysics® software complex, a number of parameters must be taken into account: 1. Selects the dimension of the model. A three-dimensional model of the electron-beam exposure process on the sample surface is constructed. 2. The choice of physics and type of research. We consider a time-dependent process - Time Dependent. To study temperature changes, the thermal conductivity module in solids is used - Heat Transfer in Solids (ht). Electron beam exposure time t = 60 s. The motion of the electron beam along the x and y-axis is specified using the Analytic and Interpolation functions. Using the deposited beam power section of the Heat Transfer in Solids module, the effect of the electron beam on the sample is described. According to the processing conditions, the electron beam is first focused on the surface of the sample, and then, using the control unit, it is converted into a raster and scans along its entire diameter. 3. Defining geometry and global variables. The sample is a cylindrical plate with a diameter of 15 mm and a height of 7 mm. The power of the electron beam P=U⋅I=20000⋅0.001=200 W. Electron beam diameter 1 mm. 4. Addition of materials. A sample of titanium alloy VT-1 was selected for the study and its main thermophysical properties were set. The initial alloy VT-1 was a mixture of two modifications of titanium α- and β-Ti. 5. Generation of a grid. In the COMSOL Multiphysics® environment, the calculation is performed using the finite element method. Before starting the study, a mesh for specimen partitioning is set. The mesh selected in the model is triangular mesh size - fine. The temperature distribution over the surface and deep into the sample in the direction of electron beam motion was determined. Processing of a sample of titanium alloy VT-1 with the help of an electron beam is carried out in scanning mode. The repeated passage of the beam over the surface leads to an increase in the total temperature of the sample being treated. The scanning frequency is set equal to 50 Hz, the process of electron beam processing is highspeed. Maximum temperatures are reached on the surface in the central part of the sample, which is associated with the trajectory of the electron beam. At the same time, temperatures in the heat exposure zone can reach 2000-2500 [degC], which indicates high heating and cooling rates in the electron beam exposure zone of the order of 10e6.

Download

- Europe_2020_Poster_Lapina.pptx - 0.22MB