See How Modeling and Simulation Is Used Across Industries

Multiphysics modeling and simulation drives innovation across industries and academia — as is evidenced by the many uses showcased in the technical papers and posters presented by engineers, researchers, and scientists at the COMSOL Conference each year.

Draw inspiration from the recent proceedings collected below, or, to find a specific presentation or filter by application area or conference year/location, use the Quick Search tool.

View the COMSOL Conference 2025 Collection

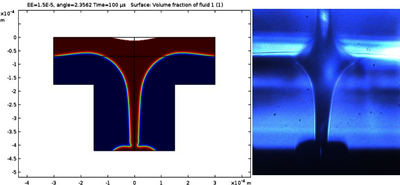

Laser-induced forward transfer (LIFT) is a non-contact direct-write technique that enables the deposition of small volumes of material into user-defined high-resolution patterns with a wide range of structural and functional materials. There are many variations of the LIFT process, each ... Read More

A Microbolometer is a specific type of uncooled infrared radiation detector used in thermal cameras, which converts the incoming energy into a proportionate electrical signal, which is then amplified, processed and displayed, typically on the thermal camera’s LCD viewer. The main ... Read More

One of the most noticeable effects in loss of performance and capacity of thermal systems is produced by altitude. This causes that the density of a compressible fluid and the atmospheric pressure are considerably reduced, causing a decrease in electrical power and thermal systems. Given ... Read More

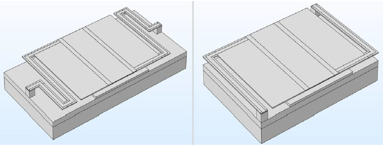

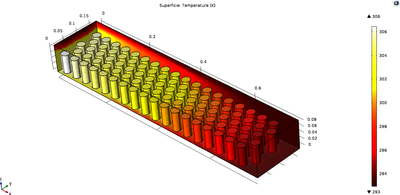

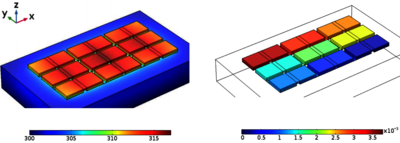

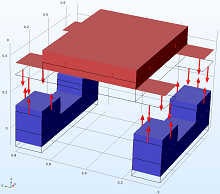

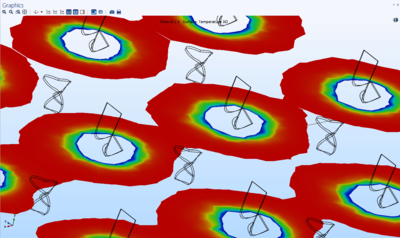

Thermoelectric generators (TEGs) which convert heat into electrical energy due to Seebeck effect, have recently attracted a great attention as green and sustainable energy sources. One of the challenges in the field of thermoelectric devices is the design optimization in order to make ... Read More

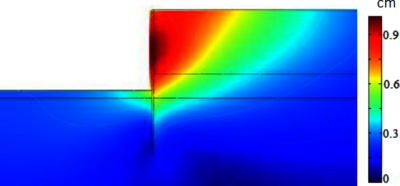

Deformation prediction is an important part of the structure stability analysis. However, the deformation of bank protection structure which is affected by many factors, such as structural stiffness, earth pressure and hydrostatic pressure. It contains a complex mechanical process, which ... Read More

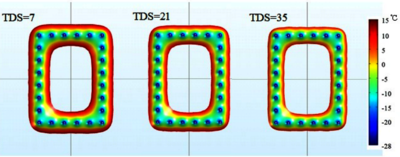

With the extensive application of ground freezing method in coastal areas, the groundwater environment during ground freezing has been changed. Especially in seawater intrusion areas, groundwater salinity is high (even salinity equivalent to sea water (ca. 35g/L)). Engineering experience ... Read More

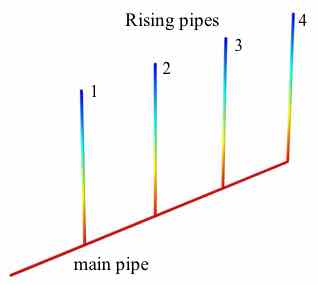

We consider the fluid dynamics problem of homogeneously filling a large tank by multiple inlets fed from a piping system. Suitable pipe geometries must be chosen so that the volume flow is constant for all inlets. In this work, we compare both for a piping system as depicted in fig. 1: A ... Read More

Machines with rotating components are prone to vibrations because an imbalance of the rotor would always act as a harmonic excitation force to the machine. Thus oscillations close to the natural frequencies are tried to pass through fast in the run-up and cast-down or even completely ... Read More

Graphene is an allotrope of carbon having the structure of a plane sp2-hybridized atom with a band length of 1.42Å, and representing the basis of any carbonaceous material. This 2D material consisting on pure forms of carbon exhibits high crystalline and electronic quality. Thus, despite ... Read More

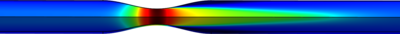

Numerical simulation tools offer the opportunity to ascertain characteristic values, which are difficult to measure. A possible approach for validating simulation models by easy measurable data and gaining the needed values is described in this study of a Venturi tube. The examination of ... Read More