In accordance with our Quality Policy, COMSOL maintains a library of hundreds of documented model examples that are regularly tested against the latest version of the COMSOL Multiphysics® software, including benchmark problems from ASME and NAFEMS, as well as TEAM problems.

Our Verification and Validation (V&V) test suite provides consistently accurate solutions that are compared against analytical results and established benchmark data. The documented models below are part of the COMSOL Multiphysics® software’s built-in Application Libraries. They include reference values and sources for a wide range of benchmarks, as well as step-by-step instructions to reproduce the expected results on your own computer. You can use these models not only to document your software quality assurance (SQA) and numerical code verification (NCV) efforts, but also as part of an in-house training program.

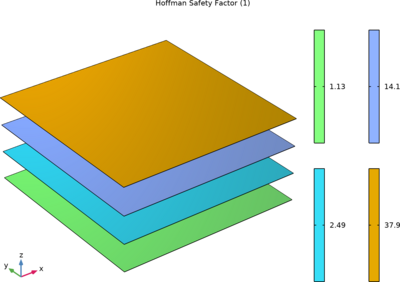

Laminated shells made of carbon fiber reinforced polymer (CRFP) are common in a large variety of applications due to their high strength-to-weight ratio. The widespread attention to laminated shells is due to their diverse applications in aerospace, marine, automotive, and various ... Read More

Powder compaction is a key process in powder metallurgy, where it gives the flexibility to produce quality products of complex shapes for sintering. The density of the compact is a key factor to determine the overall quality of the sintered product, as regions with lower density could ... Read More

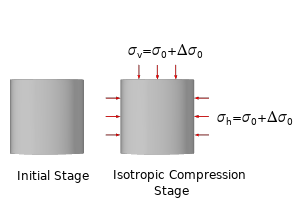

This model simulates the isotropic compression of naturally structured and artificially structured clays using the Modified Structured Cam-Clay (MSCC) material model. The aim of the example is to reproduce the compression behavior given in a benchmark for four structured clays. Read More

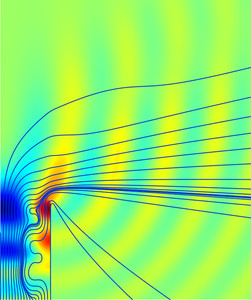

This example models the radiation of fan noise from the annular duct of a turbofan aeroengine. When the jet stream exits the duct, a vortex sheet appears along the extension of the duct wall due to the surrounding air moving at a lower speed. The near field on both sides of the vortex ... Read More

In this example, wrinkling is studied in a cylindrical membrane of nonuniform thickness under axial and pressure loading. The membrane is modeled as an incompressible Mooney–Rivlin material. During axial stretching, certain portions of the membrane undergo wrinkling; however, the ... Read More

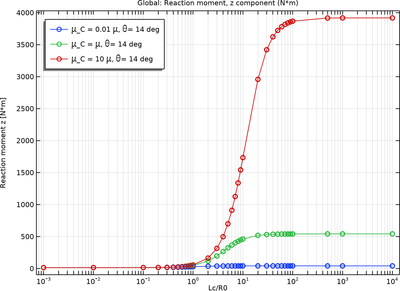

In this example, it is demonstrated how to extend the built-in linear elastic material model to a Cosserat material through the addition of microrotation degrees of freedom. A cylindrical bar under pure torsion is analyzed and the effect of the Cosserat length scale parameter on the ... Read More

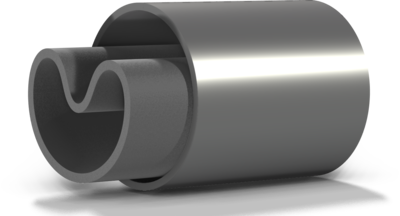

Due to the demand for larger power with a smaller size, dual-shaft systems with intershaft bearings are becoming a standard configuration for gas turbine engines. Such systems consist of two coaxial rotors running at different speeds, interlinked through a multi-spool bearing. In this ... Read More

In this example, the Bergstrom–Bischoff material model is used to model the temperature and strain dependent behavior of High Density Polyethylene (HDPE) used, for example, to make liners for damaged pipes in oil and gas applications, or to make type IV hydrogen storage vessels for fuel ... Read More

For slender structures, buckling is a catastrophic instability if the service load is above the critical limit. For such structures, it can be important to study the behavior of the structure beyond the critical buckling load, which is known as postbuckling analysis. Tracing the ... Read More

The fabrication of a cup through powder compaction is simulated in this tutorial model. The powder compaction process is becoming common in the manufacturing industry, due to its potential for producing components of complex shape and high strength. Combining the Fleck–Kuhn–McMeeking ... Read More