A Continuous-State Modeling Framework for Phase Change Materials in COMSOL Multiphysics

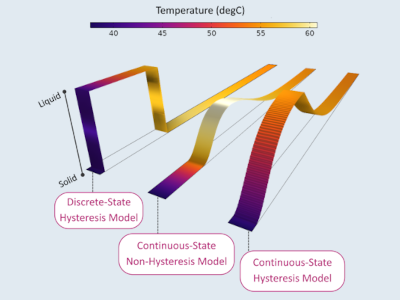

Phase change materials (PCMs), including shape memory alloys (SMAs), often exhibit thermal hysteresis behavior during phase transitions. Traditional modeling approaches employ binary or threshold-based phase transition models, which is often sufficient for steady-state applications or scenarios where heating and cooling cycles fully saturate the material. However, these models can fall short for capturing complex behavior such as transformations that occur over a range of temperatures, involve spatial gradients, or require accurate representations of thermal hysteresis and partial phase states.

A continuous-state modeling framework is proposed for phase change materials in COMSOL Multiphysics that captures the gradual evolution of material state, allowing the simulation of intermediate phases and history-dependent transformations. By incorporating experimental data such as Differential Scanning Calorimetry (DSC) measurements, the model reproduces temperature-dependent material behavior with high fidelity, including latent heat effects and the characteristic looped response seen during heating and cooling cycles. These methods employ COMSOL’s Heat Transfer Module and the State Variable utility node.

Building directly from Walter Frei’s 2016 COMSOL Blog article, “Thermal Modeling of Phase-Change Materials with Hysteresis,” this model tracks a state variable representing a continuous phase transition fraction. The effective total specific heat of the end and intermediate phase states are implicitly defined by the imported DSC characterization curves. Reversal of the heating/cooling process in intermediate states follows a thermally conservative “outer loop” model, which maintains the current phase transformation fraction with sensible heat gain/loss until the appropriate transition curve is reached. A “virtual DSC” simulation model employing this framework was found to be able to effectively replicate the output of empirical DSC testing, including in cases with multiple inflections in the sample heat flow during transformation.

The continuous-state framework improves predictive accuracy in simulations involving gradual or spatially variable phase transitions and enables more realistic simulation of systems where phase change plays a critical role by capturing partial transformation and thermal memory effects. These methods offer improved accuracy for general PCM modeling and can be particularly valuable for materials with nonlinear or hysteretic thermal responses such as SMAs or paraffin-based PCMs.