A hybrid energy harvesting based on lead free piezoelectric materials at constant temperature

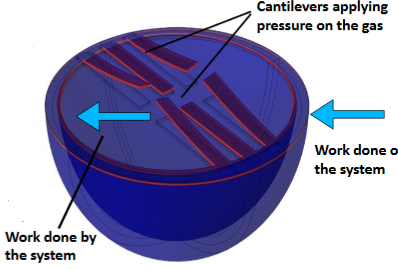

Within the ENHANCE European project, hybrid energy harvesters have to be designed and developed to supply small and autonomous sensors in automobiles. The focus of this work is particularly related to the harvesting of energy from the vibration of the vehicle and from the high temperature (in fluctuation or not) around the engine. To this aim, an ideal hybrid energy harvester should be able to harvest vibrational energy at lower frequency ranges (>500 Hz) and pyroelectric energy at a higher temperature range. However, pyroelectric effect work with a time-varying temperature. Furthermore, the use of lead based piezoelectric materials as usual creates an environmental concern due to lead-toxicity. In this paper, a hybrid energy harvester has been designed using Lithium niobate piezoelectric material, shape memory alloy, polyvinyl difluoride, piezoelectric polymer and helium gas, and its performance has been investigated using COMSOL Multiphysics® finite element method (FEM) software for rapid validation of the proof of concept and for vizualization of the transducer functioning. The proposed hybrid harvester is capable of converting both vibrational mechanical energy and constant temperature energy into electrical energy. The principle behind the constant temperature conversion is based on the Joule-Thomson physical principle. Different transducer design and material configurations have been evaluated to identify the optimum conditions, materials, and design of the hybrid transducer. For the FEM analysis, Solid mechanics, electrostatics for piezoelectricity, heat transfer in solids, heat transfer in fluids, electric currents chemistry modules have been used for pyroelectricity and associated thermodynamic properties in global definitions as well as for the vibrational piezoelectricity. The simulation demonstrates that the hybrid harvester was able to generate energy the constant temperature, as predicted. The harvester has a volume of 12.21 cm3 and can work at a constant temperature between 20 and220 °C, and surrounding mechanical vibration 0- 500 Hz of frequency. On the one hand, the harvester was able to work for up to 8 hours under constant temperature. On the other hand, the calculated stored energy was 8.92 µJ at 271Hz of mechanical vibrational excitation. This lead-free piezo-pyro energy harvester is a promising device which can be used for environmental purposes, especially in automobiles. Its high-temperature performance stability, energy harvesting at constant external temperature, piezoelectric energy harvesting at lower frequencies, and lead-free nature make it an ideal to be used as energy harvester and supplier for small appliances.

Download

- neetu COMSOL .pdf - 0.75MB

- COMSOL poster_neetu kumari.pdf - 1.28MB