Coupling Non-Newtonian Fluid Flow and Heat Transfer Inside a Scraped Surface Heat Exchanger

Scraped-surface heat exchangers (SSHEs) handle products that are viscous, that contain particles, and that tend to deposit on the heat transfer surface. The rotating scraper blades continuously remove any deposition on the heating or cooling surface, thereby maintaining the efficiency of heat transfer and enabling extended runs without fouling. SSHEs are extensively used in processing products which undergo structural transformations that induce high viscosity. SSHEs are also employed to investigate the effects of shear rates on food microstructure in systems such as oils, milk fat, whey proteins, chocolate, emulsions, starch and ice creams [1].

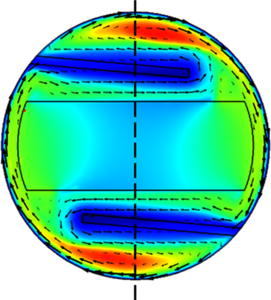

In the suite of previous experimental and modeling studies [2], a tridimensional (3D) numerical model was implemented for studying the fabrication of a commercial lemon sorbet inside a SSHE. Phenomena were represented with the help of the COMSOL Multiphysics® physics interfaces Laminar Flow and Heat Transfer in Fluids and the Non-Isothermal Flow Multiphysics coupling, ensuring the conservation of energy, momentum, and mass in the fluid as well as the conservation of energy in the solids. Viscous dissipation was considered. In the model, only the main elements of the SSHE (refrigerated cylinder, dasher, two scraper blades) were represented; the SSHE inlet and outlet bowls were simplified in order to allow steady-state simulation without moving geometry. The flow was calculated in the frame which rotates with the dasher and the blades; in this frame the cylindrical heat exchange surface is perceived to be rotating at the rotor speed but on the opposite sense of rotation. Inside the SSHE cylinder, the fluid motion is confined between the inner wall, the dasher and the blades. Conduction was solved throughout the dasher and the blades; continuity of temperature and heat flux was assumed at the interface between the fluid and the solids. The influence of temperature on the sorbet's density, thermal conductivity, heat capacity and consistency coefficient was considered, including the sharp changes that occur at the initial freezing temperature -2.72 °C. In the model, the fluid was assumed to be incompressible and characterized by a power-law apparent viscosity with behavior index 0.5. The following SSHE operating conditions were considered: rotational speed 750 rpm, flow rate 50 kg/h, inlet temperature 5 °C, and refrigerant evaporation temperature -15.3 °C.

Model predictions of temperature did agree within 0.1 °C with observations performed in the central region of the SSHE, indicating the reliability of the approach. As a second step, we are assessing the fragmentation of air bubbles, which play a key role in defining the sorbet texture. The COMSOL Multiphysics® interface Transport of Diluted Species was included in the 3D model and employed in diagnosing the critical radius of bubbles. It appears that the smallest bubbles are generated a) near the contact between the blades and the scraped surface, where the highest shear rate is reached, and b) in the coldest region, where the continuous phase has the maximum apparent viscosity.

References

[1] Rao and Hartel, 2006, Critical Reviews in Food Science and Nutrition.

[2] Hernandez-Parra et al., 2018, Journal of Food Engineering.