Design and Analysis of an Electrostatic Precipitator for a Diesel Particulate Filter

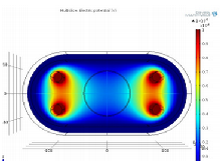

Gaseous exhaust of different industries contains dust particles of different chemical precipitates that are harmful for the environment. Electrostatic Precipitators are very often used in industries like power plant to filter their gaseous exhaust and to prevent the atmosphere to being polluted. Electrostatic Precipitators are very efficient in dust particle collection from the flue gas. Electrostatic Precipitators use the force of the electric field to separate the dust particles from gaseous exhaust. Electrostatic Precipitators charge the dust particles and remove these particles by attracting these charged dust particles toward the collecting plates. The charging of dust particles requires a charging zone. When gas passes through that charging zone, the dust particles in the gas stream become charged and then these charged particles are attracted toward the collecting plates. The design of an Electrostatic Precipitators requires the knowledge of its working principle and the problems that often arise during its working. The main reason for problems in working of an Electrostatic Precipitator is the dust resistivity re-entrainment and back corona these are due to the ionization volume and flow velocity of the particles. This dust resistivity, re-entrainment and back corona affects the collection performance of an Electrostatic Precipitator. It is proposed to implement a model of ESP for automobile exhaust system to reduce the exhaust dust. Using COMSOL Multiphysics® software, the proposed model of ESP was designed and simulated for ionization volume and flow velocity of the ESP in a static condition.

Download

- manoj_abstract.pdf - 0.3MB