Design of a trailing shield for arc welding and arc additive manufacturing processes

Manufacturing of metal component in industry involves many kind of processes where materials experience high temperature and changes of state. Then, oxidation may become a significant topic regarding industrial requirement and specification. This issue is well-known in welding applications, where inert gas flow is used for both initiating electrical arc plasma and shielding of hot areas. However, it appears that design of shielding device is mainly based on an empericalempirical approach and welder skills. This study aims at providing a self-consistent and multi-physic modelling of gas flow able to deal with oxidation issue and support design of a new diffuseurdiffuser. Robustness of the device will be assess for different configurations: internal design, flow rates, workpiece-nozzle distance, gas chemical composition, position). Consequently, efficiency of the device will be studied for welding applications but additive manufacturing applications will be investigated too.

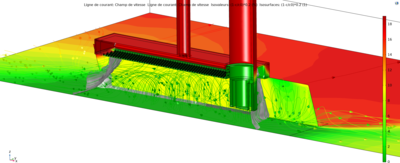

Current work is based on implementionimplementation of a CFD modelling with chemical species transport. Navier-stokes equations are solved assuming a compressible steady-state flow and turbulence phenomena are caughttched with RANS method (SST model). A two-way coupling allows to deal with density variations based on local molecular composition and extra molecular diffusion due to eddies . A small scale resolution highlights how the flows are distributed inside the diffuseur and how velocities are smoothed. Outlet velocities are used as inlet boundaries conditions for a large scale resolution. First qualititivequalitative analysis shows how bBuoyancy may affect free flows and how occurenceoccurrence of Coanda effect could degrade quality of shielding.

While this study focused on shielding device, next steps shall emphase deal with heat and momentum from the electrical arc plasma and motion of the apparatus to be representative of the application.

Download

- paper_Morville.pdf - 1.11MB