Effect of Substrate Contact Angle on Ink Transfer in Flexographic Printing

Flexography is a roll-based mass printing process used in manufacture of printed products such as sensors, self-cleaning surfaces, and flexible electronics. Flexography involves inking of a stamp wrapped around a roller, and the transfer of ink on the stamp surface to a printing substrate as the roller rotates against it.

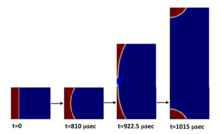

Ink transfer ratio from the stamp surface to the printing substrate is an important parameter of the system, as it determines printing quality and the thickness of the printed product. In this study, ink transfer from the stamp to the printing substrate is simulated for two cases (equal and unequal contact angles on the two surfaces) using the moving mesh interface, and the laminar two-phase flow, phase field interface in microfluidics module of COMSOL® software.

Simulation results indicate an increase in ink transfer ratio to the substrate, as the ink contact angle on its surface is reduced.

Download

- hizir_presentation.pdf - 1.42MB

- hizir_paper.pdf - 1.51MB

- hizir_abstract.pdf - 0.2MB