Experimental Validation of a Multidimensional Model for an Indirect Temperature Swing Adsorption Unit

Temperature Swing Adsorption (TSA) processes are applied for the removal of impurities from various gas streams. The limiting factor of a TSA process is the regeneration step, which is characterized by long heating and cooling times. To reduce the regeneration time, indirectly heated and cooled adsorbers were developed: the adsorbent bed is heated or cooled indirectly via a heat transfer fluid that is not in direct contact with the adsorbent [1]. This indirect heat transfer can be established e.g. in a tube and shell heat exchanger adsorber. With this new TSA concept, bulk separation becomes economically feasible, which enables new fields of application.

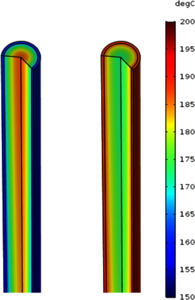

A pilot plant has been built up to investigate the adsorptive CO2 removal with indirectly heated and cooled adsorbers. A three adsorber process to remove CO2 from a N2/CO2 mixture was realized. The process comprises an adsorption and a regeneration phase. The regeneration phase consists of three steps: Heating, purging with purified N2 product and cooling. In a previous work [2] a mathematical model was developed and implemented in COMSOL Multiphysics® to describe such a TSA process. The adsorber tube is represented by a 2D axial symmetric model that is coupled to a 1D model for the heat transfer fluid. The used physics interfaces are: Heat Transfer in Porous Media (including solid and fluid domain conditions), Darcy´s Law, Transport of Concentrated Species and a Coefficient Form PDE to describe the adsorption. This model was modified and expanded to describe the laboratory experiments. The results of heating and cooling measurements were applied to adjust model parameters for the heat transfer. Furthermore, the results of breakthrough experiments were compared with the simulation to verify the adsorption kinetics.

In order to validate the model, the simulated results will be compared with the experimentally determined values at steady state. Multiple cycles were calculated using the LiveLinkTM for Matlab®. For the model validation, the axial temperature profile of one adsorber and the CO2 desorption behavior will be compared. The CO2 desorption is characterized by the CO2 concentration in the offgas during the regeneration phase and the offgas stream itself. Altogether, the simulation is in good agreement with the experiment.

References

[1] J. Bonjour et al., Temperature Swing Adsorption Process with Indirect Cooling and Heating, Ind. Eng. Chem. Res., Vol. 41, p. 5802-5811, (2002)

[2] G. Salazar Duarte et al., Modeling and Simulation of a Tube Bundle Adsorber for the Capture of CO2 from Flue Gases, Chem. Ing. Tech., Vol. 88, p. 336-345, (2016)