FEM Simulation of Interdigitated Electrodes (IDEs) Device

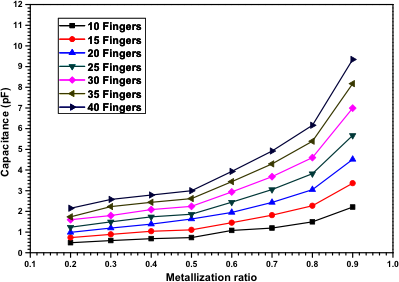

In this, FEM simulation of the interdigitated electrodes (IDEs) device using COMSOL Multiphysics® is presented. In this study, the effect of meshing sequence on the performance of IDEs device was evaluated using normal as well as adaptive mesh refinement. The key parameters such as of the number of fingers, metallization ratio (gap to width ratio) and thickness of medium were considered for performance evaluation of IDEs device. MATLAB® R2017b has been used to model IDEs device. LiveLink™ for MATLAB® module was used to import model in COMSOL® environment. Electrostatics as well as electric current study present in ac/dc module available in COMSOL® were used to analyze the electrical properties of IDEs. Simulations were performed by considering necessary material properties, material for each physical layer was assigned using a built-in material library. Numerical simulation of IDEs with variation in the number of electrode fingers, metallization ratio and thickness of medium were carried out to find with variation in to visualize the optimum set of parameters. Figure 1 shows the effect of metallization ratio on IDEs performance with varying number of electrode fingers. A metallization ratio of 0.7 found to be optimum for IDEs. Adaptive meshing sequence predicted better results for higher electrode finger pairs 30-50 compared to 10-20 electrode finger pairs. The simulation result will be useful for the optimum design of the IDEs device for biosensing applications.