Knowledge and Skills Acquisition via a “Parallel” Problem Solving Approach

To be competitive in today’s workforce, students in STEM undergraduate programs are expected to develop problem-solving skills. Often, this occurs through guidance and practice in the form of assignments, labs, experiential learning opportunities, teamwork, and other means. The concept of a T-shaped engineer [1] represents an engineer with deep content knowledge and awareness of engineering systems as well as multidisciplinary skills (e.g., problem-solving skills, entrepreneurship, etc.), and such skills are further emphasized by the National Academy of Engineering when communicating attributes that the engineer working in the year 2020 would ideally possess [2]. ABET which accredits engineering programs has also communicated a variety of outcomes that students need to achieve in undergraduate programs [3], one being that students must exhibit “an ability to use the techniques, skills, and modern engineering tools necessary for engineering practice.” Such tools might include computational software and hardware, critical and creative thinking skills, respect, etc. A challenge lies in how to effectively and efficiently ensure that students develop not only technical content knowledge but also multidisciplinary skills.

A new pedagogical approach is being explored in the Department of Chemical Engineering at Tennessee Technological University in which teams are challenged to solve a given engineering problem using each of four approaches: 1) thought exercises, 2) analytical solution methodologies, 3) experimentation, and 4) computational/simulation-based approaches with emphasis in using COMSOL® [4]. As one example, the following problem statement was recently given to students in a senior-level biotransport course:

A porous shell containing a drug molecule is delivered into a compartment in the body at time zero. Drug is released from the shell through the shell’s porous wall and into the compartment which is assumed to be well-mixed. Estimate the concentration of the drug in both the shell and in the well-mixed compartment.

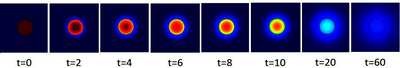

The problem was motivated to promote the development of the aforementioned T-shaped engineer and by a paper authored by Farrell and Verrnengo [5] in which complementary approaches to characterizing transport from alginate beads were described. For the problem, the thought exercise was a think-pair-share while the analytical solution involved development and solution of equations with appropriate initial conditions to produce normalized concentration profiles. For experimentation, alginate beads containing a red food coloring as a “diffusible tracer” were prepared, and the normalized concentration of the tracer in a stirred water domain around the beads was determined. A simulation was then performed using COMSOL® and Transport of Diluted Species physics. Time- and spatially-dependent profiles of tracer concentrations in simulated beads (with “Thin Diffusion Layer”) and water domains were found, and normalized concentrations were compared/contrasted to those from the other methods.

Ultimately, the four techniques provide students with an opportunity to approach a single problem from various perspectives, resulting in a hopefully-increased understanding of multiple aspects of the problem. Future efforts will focus on development of other problem statements and in assessing the impact of the approach in increasing students’ knowledge of course content and developing tools to be engineers with a myriad of problem-solving skills.

References and Attribution: 1. Rogers, P., & Frueler, R. J. (2015). The “T-shaped” engineer. American Society of Engineering Education (ASEE), Proceedings of the Annual Meeting, Seattle, WA, June. 2. National Academy of Engineers [NAE]. (2005). The engineer of 2020: Visions of engineering in the new century. National Academy of Engineering. 3. Accreditation Board for Engineering and Technology [ABET]. (2017). General criterion 3: Student outcomes. 4. COMSOL is a registered trademark of COMSOL AB. 5. Ferrell, S. and J. Vernengo. A Controlled Drug-Delivery Experiment Using Alginate Beds. Chemical Engineering Education. 46(2): 97-109, Spring 2012.

Download

- sanders_poster.pdf - 0.87MB

- sanders_abstract.pdf - 0.31MB