Large Scale 3D Flow Distribution Analysis in HTPEM Fuel Cells

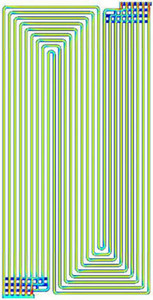

Accurate bipolar-plate and flow-field layout is one crucial task for optimizing fuel cells. These cell components perform several functions, including charge transport or gas and water transport throughout the cell just to name a few. Overall, the design depends on the fuel cell application or the geometrical size of the assembly. The requirements for a flow-field used in a high temperature polymer electrolyte membrane (HTPEM) fuel cell (operated at temperatures around 130-180°C) differ from the ones that are important for polymer electrolyte membrane (LTPEM) fuel cells, mainly operated around 80°C. In a HTPEM fuel cell, liquid product water is not present during operation, thus porous media flooding is less of a concern. Nevertheless, large quantities gradients should be avoided. Uniform fluid-flow is of utmost importance.

Download

- Siegel_pres.pdf - 2.1MB

- Siegel.pdf - 0.48MB