Modelling Contact Heating of Solid Food Products

Despite its wide use in industrial or culinary conditions, contact heating has not been extensively studied in the literature devoted to food products. This is mainly due to the difficulty in measuring in a non-invasive way the heat flux transferred as well as the thermal contact resistance between the heating and the heated surfaces. This lack of knowledge is also to the difficulty in modelling all the coupled heat and mass transfer phenomena as well as physic-chemical transformations occurring in the zone of the product close to the heating surface (intense drying or crusting of this zone inducing a deformation of the product's surface, evaporation of the water released from the product when heated...).

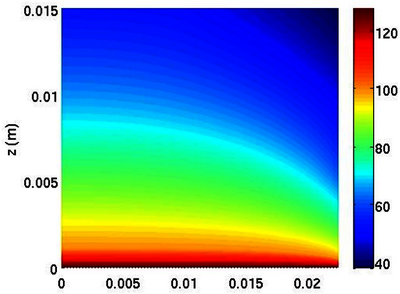

In this study, the experimental data obtained from a laboratory heating device specially designed to study contact heat transfer were used to develop and validate a coupled heat and mass transfer model able to predict product local moisture loss and temperature rise kinetics during heating. A slice of potato was used as heated sample. Considering the shape of product temperature rise kinetics, the model developed considers the formation and propagation of a 2D-boiling front of water through the product during contact heating. At a given heating time, the product in hence divided in two zones of variable volume : a dried lower zone (called crust) assumed to oppose no-resistance to vapour transport but opposing a significant resistance to heat transfer and a upper moist zone where heat and mass transport were described using classical Fourier's and Fick's laws. COMSOL Multiphysics®

and the Deformed Geometry Interface were used to solve the equations of the model. A very good accordance was observed between experimental results (temperature within the product at three locations, product overall mass loss).

Based on the simulation results, it was concluded that the formation of the crust at the lower surface of the product played a key role in the overall heating of the product since its resistance to heat transfer is, in some conditions, far higher than the thermal contact resistance existing between the heating surface and the heated product.

Download

- Cambridge_2019_Vine.pptx - 0.42MB

- 0057_Bertrand Broyart_Cambridge_2019_Vine_PDF.pdf - 0.61MB