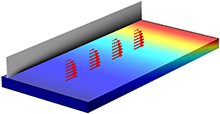

Multiphysics Analysis of a Photobioreactor

Photo-bioreactors generate biomass by providing a controlled environment for the cultivation of algae due to photosynthesis. Algae cultivation can be controlled through the operating parameters and bioreactor environment to allow for high productivity and the use of systems with large surface-to-volume ratios offers maximum efficiency in the use of light compared to alternative batch systems. Extension to closed Photo-bioreactor systems provide more stability by improving control of the internal environment allowing a more uniform temperature distribution, better control of gas transfer and reduced evaporation of the growth medium. High productivity systems generally operate as a closed system and require close control of factors such as carbon dioxide supply, water supply, optimal temperature, efficient exposure to light, culture density, pH levels, gas supply rate, mixing regime, etc. to produce an optimal culture environment.

To assist in the development of improved reactor designs and operating conditions a computational model has been developed using COMSOL Multiphysics® software that includes species convection and diffusion in both liquid and gas phases, mass transfer between phases, chemical kinetics within the liquid phase, calculation of pH, and calculation of light penetration into the water.

Download

- crompton_presentation.pdf - 1.53MB

- crompton_abstract.pdf - 0.13MB