Nuclear PWR Analysis: Backup Power Response Time as a Function of Pressurizer Size

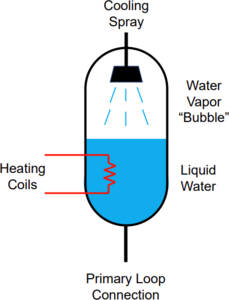

A pressurizer is a specialized vessel used to regulate pressure in the primary coolant loop of pressurized light water nuclear reactors (PWRs). During normal operation heat lost to the surrounding environment is replaced by heating coils in the pressurizer tank to maintain system pressure. It is important that coolant pressure in the plant’s primary loop remain high enough to prevent the formation of vapor bubbles (voids) which affect the heat output of nuclear fuel in the reactor core. Additionally, in severe accident scenarios where it is assumed that coolant circulation ceases due to a loss of grid power, the volumetric capacity of the pressurizer in part determines the minimum response time of back-up power generators (that is the speed with which they must restore coolant flow). Normally, the pressurizer operates at saturated conditions whereby it is filled with a liquid-vapor coolant mixture. When coolant circulation stops, pressure begins to rise gradually in the reactor core. As coolant in the reactor expands, the liquid level in the pressurizer rises. Once the pressurizer is nearly filled with liquid, system pressures rise dramatically, and irreversible system changes can occur such as damage to hydraulic components or activation of safety devices like rupture disks. In order to prevent such scenarios, the pressurizer may be sized with sufficient capacity to accommodate coolant expansion during a loss of grid power allowing backup systems to restore power and coolant flow.

This paper presents a computational fluid dynamics (CFD) model of a nuclear reactor core and uses a multi-scaled approach to estimate the relationship between the size of the pressurizer and the required response time of backup generators to restore coolant flow.